Need to Remove Solids from Your Process Water?

Sand and gravel producers are burdened by sediment in their process water. Clearwater Industries wastewater treatment systems remove sediment and return clean water for reuse.

Settling Pond Problems

Settling ponds, also known as settling basins, decant ponds, or tailing ponds, are used for process water sedimentation. This process can be slow and requires a large site footprint. Mucking ponds and shutting down early to ‘let it settle’ kills production hours.

Reduce Settling Pond Management

Polymer systems reduce pond cleaning time and operating costs and help meet regulatory issues. Polymer flocculants capture solids and fines to settle quickly. Settled solids provide continuous clarified water for your production and thick mud that is easy to remove.

Turnkey clarifiers connect with your sand and gravel wash plant, reducing or eliminating settling ponds. Discharge waste sludge to its final resting place and never double-handle material again.

Polymer Make-Down Units

You can reduce settling pond management by increasing sedimentation rates with polymer flocculants.

Polymer Make-Down Units properly activate, age, and dose polymer flocculants. Our polymer preparation units offer automatic and manual controls for a consistent flocculant solution strength.

Clarifiers & Thickeners

Clarifiers allow you to reduce your settling pond footprint or eliminate them. Our High Compaction Clarifiers can treat 300-15,000 GPM, achieve +65% solids by weight discharge and return +90% of clarified water to the process. Portable clarifiers keep you operating wherever your site is or when current systems break down.

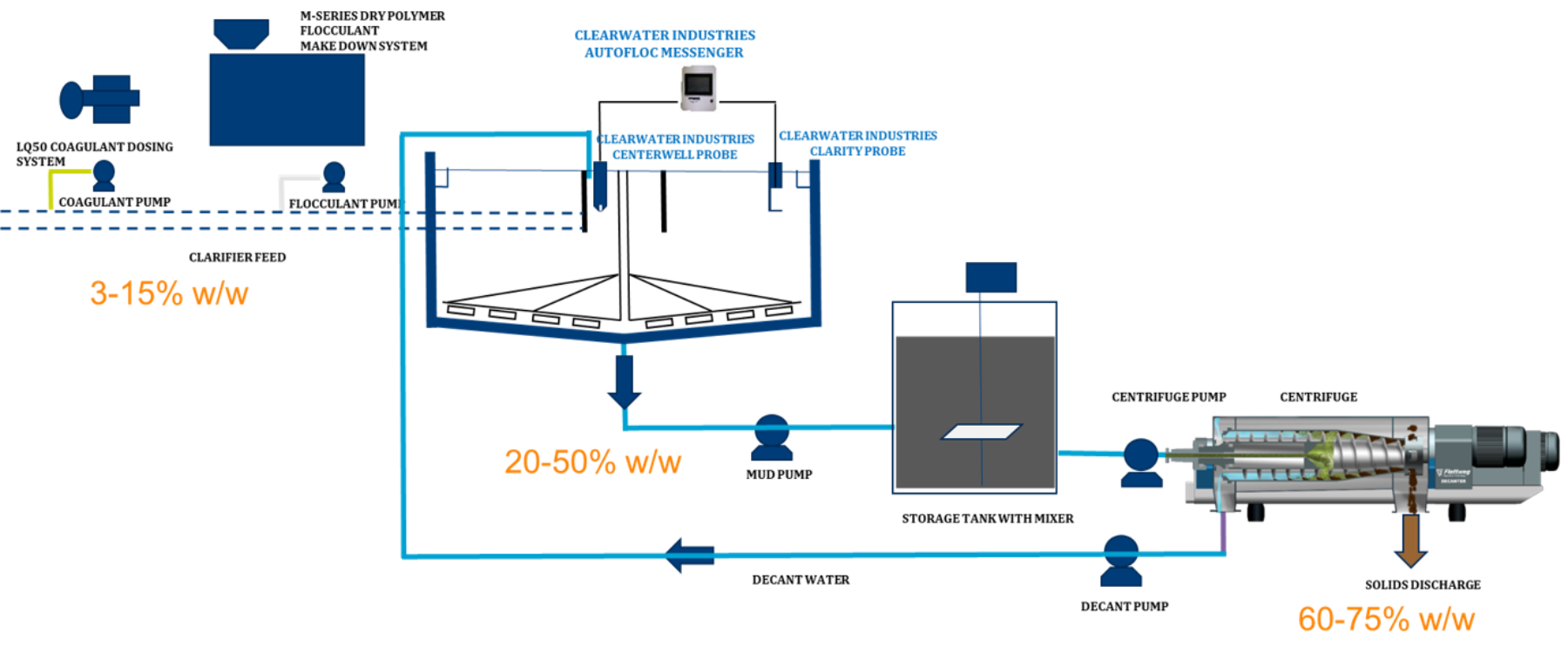

Closed Loop Clarification & Sludge Dewatering

A closed loop clarification and sludge dewatering system provides sand and gravel producers a +75% solids by weight cake for disposal and +90% of their process water for reuse. The closed-loop system allows you to eliminate settlings ponds.

Combining a polymer flocculant preparation system, clarifier, centrifuge, and automation instruments, aggregate producers can continuously manage their wastewater with little operator attention. Our High Compaction Clarifying Thickeners achieve +50% solids by weight sludge alone. By adding a centrifuge to dewater the sludge further, producers can reach 80% solids by weight, providing a spadeable and conveyable material.

Want to save time and money spent on polymer dosing?

The AutoFloc Dosing System eliminates the guesswork of polymer flocculant dosing. Stainless steel probes read the polymer and slurry reaction and communicate with the digital messenger, which adjusts dosing accordingly. The AutoFloc system maximizes flocculant efficiency, minimizes consumption, and acts as a full-time operator managing the polymer dosing. It can be coupled with polymer preparation systems and comes standard on our clarifiers.