Liquid polymer, also called emulsion polymer or emulsion flocculant, separates solids from liquids and thickens sludge for mechanical dewatering.

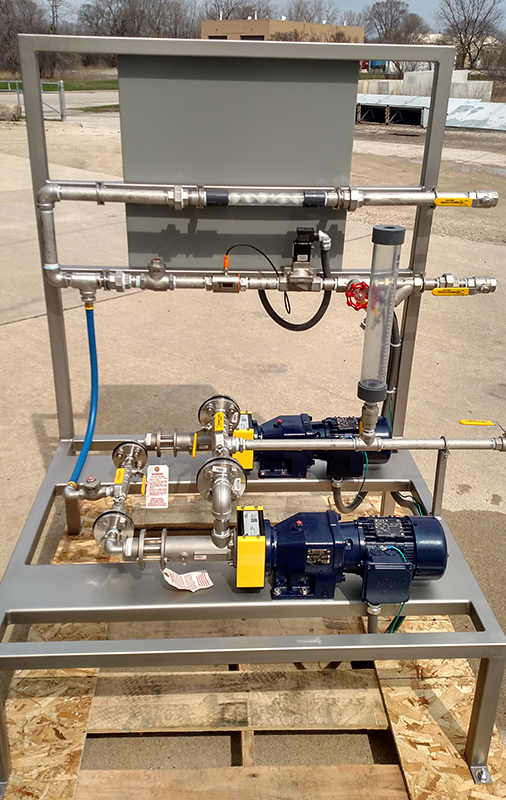

Like dry polymer, preparing and dosing liquid polymer accurately and reliably is a crucial component of a smooth-running operation. Our liquid polymer dosing systems feature variable frequency drive controls (VFDs), piston pumps, and calibration columns for consistent dosing.

We manufacture dry and liquid polymer make-down systems for applications that require both options. The flexibility of our MSSL line allows you to dose dry or liquid polymer.

LIQUID POLYMER SYSTEMS

The Clearwater Model LQ50 rapidly makes down and injects liquid polymers into wastewater streams, aiding in separating the solids from the water.

Optimal For:

- Minimizing equipment costs

- Administering coagulants and other pre-treating agents

- Low quantity polymer consumers

- Providing a simple, inexpensive solution to wastewater issues

Equipment Functions:

- Accurately mixes and injects a liquid polymer

- Creates a fully inverted creamy polymer solution

- Administers a site-specific solution at an adjustable-rate

Features:

- Inline static mixer ensures proper mixing of the polymer

- Able to be “up and running” 20 minutes after arrival

- Rugged industrial design to withstand harsh conditions

- Very little operator attention required

- Elevated skid for ease of service

- Variable stroke piston pump and calibration column for accurate dosing

Make Down Pump

- ⅓ HP Centrifugal Pump

- 115/230 Volt Single phase

- 25 GPM at 20’ of head

Neat Emulsion Pump

- Simplex piston pump

- 1” diameter piston size

- 14 GPH, 60 strokes per minute

- ¼ HP 115 VAC

- Stainless Steel wet end

Dimensions

- 48” x 40” x 32” (h)

- 240 lbs

Field Requirements

- ¾” line from emulsion to skid

- ¾” NPT clean water hook-up

- ¾” solution discharge line

- Single point electrical hookup

- 120V Single Phase 20A

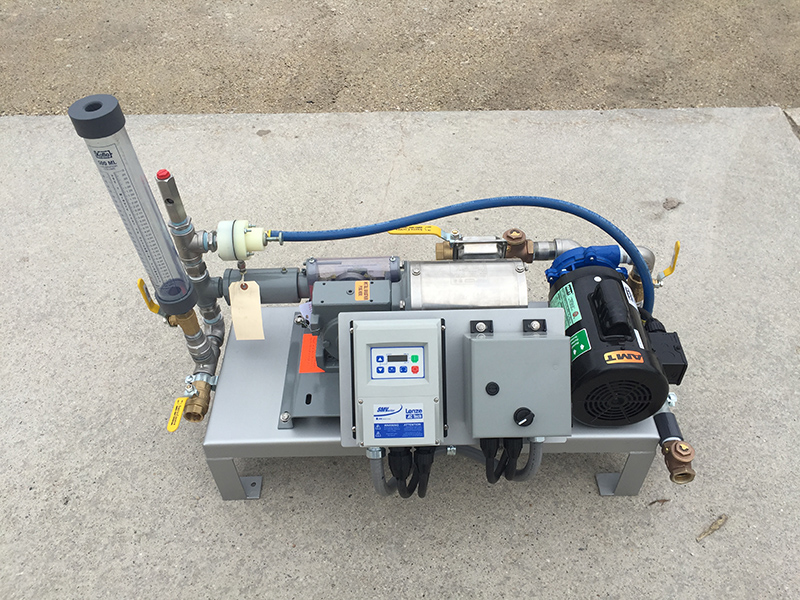

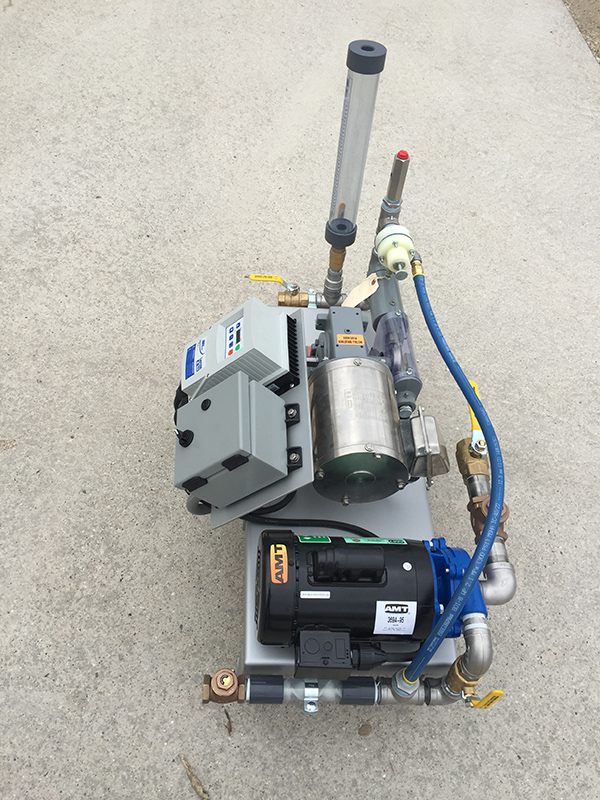

The Clearwater Model LQ25 rapidly makes down and injects liquid polymers into wastewater streams, aiding in separating the solids from the water.

Optimal For:

- Minimizing equipment costs

- Administering coagulants and other pre-treating agents

- Low quantity polymer consumers

- Providing a simple, inexpensive solution to wastewater issues

- Accurately mixes and injects a liquid polymer

- Creates a fully inverted uniform polymer solution

- Administers a site-specific solution at an adjustable-rate

- Able to be “up and running” 20 minutes after arrival

- Rugged industrial design to withstand harsh conditions

- Very little operator attention required

- Elevated skid for ease of service

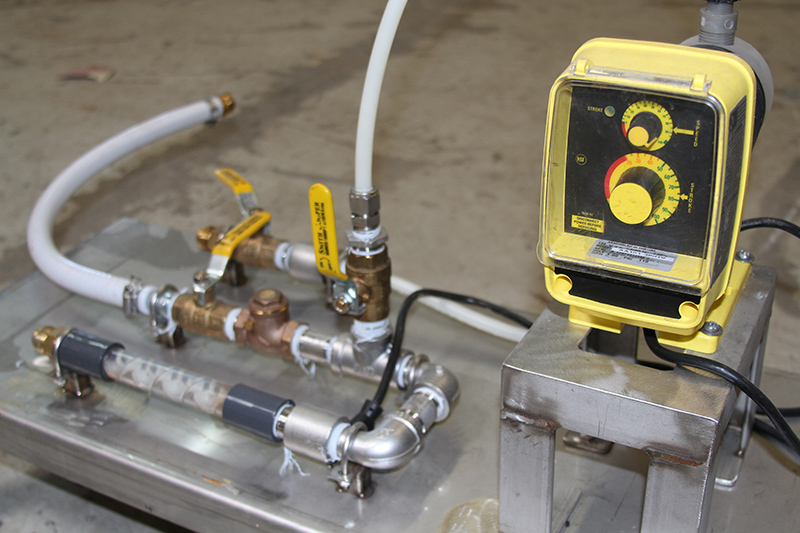

- Variable stroke metering pump

- Inline static mixer ensures proper mixing of the polymer

- 25 GPM at 20’ of head required

- Neat Emulsion Pump

- LMI Electronic metering pump

- ½” 00 Tube connections

- 1 GPH, 100 strokes per minute

- Stainless Steel construction

- 45” x 15” x 18” (h)

- 140 lbs

- ¾” line from emulsion to skid

- ¾” NPT clean water hook-up

- ¾” solution discharge line

- Single point electrical hookup

- 110 V Single Phase

Custom Liquid Polymer Systems

Clearwater Industries prides itself on working with our customers to design the optimal polymer system for their specific application. We manufacture liquid dosing systems for any application and flowrate.

DRY & LIQUID POLYMER SYSTEMS

The Model 500SSL is a dry and liquid polymer make-down and injection system. It can pump 7.9 GPM of fully activated polymer solution (9.9 lbs/hr of dry polymer is consumed if making .25% solution strength).

- Rapid separation of solids from water

- Flocking solids in clarifiers, thickeners, and settling ponds

- Freeing up land by eliminating all but one settling pond

- Greatly reducing the time and cost of cleaning out settling ponds

- Thickening solids going to centrifuges, presses, gravity belts, or other dewatering devices

Equipment Functions:

- Accurately meters, mixes, and ages dry chemical and water, creating a liquid solution

- Produces a uniform solution without the formation of “fish-eyes.”

- Administers a site-specific solution at an adjustable-rate

Features:

- Fully automatic, continuous batching operation

- Easily installed and often operational within one hour of arrival

- Extremely rugged industrial design

- Minimal operator attention required

- Can make down either dry cationic or anionic polymers

- Single tank design with internal baffles and weir ensure proper mixing and aging of polymer

- Integrated low water flow protection

- The service-friendly design includes quick disconnect couplings, elevated frame, removable pump skid, anti-seized stainless steel fasteners, and quick-disconnect hoses.

- NEMA 4 enclosure

- Hand/Off/Auto switches and relays control the automatic sequencing of the process

- 480-volt motors with 110-volt logic and controls

- Standard systems come equipped with three Variable Frequency Drives (VFDs)

- The first VFD controls a 1/2 hp stainless steel volumetric dry polymer feeder that is tied to the flow of dilution water into the polymer system (measured by IFM magnetic flow meter). This ensures a consistent solution strength is maintained

- The second VFD controls a 1.5hp electric mixer with a gear reducer to power the prop mixer in the mixing chamber

- The third VFD controls the rate at which the polymer pump (0-12 GPM standard, 40 psi max discharge pressure) sends an aged solution to process. This VFD can respond to a 4-20mA input signal in the event of an Auto-Floc dosing system being in use

- Complete with breakers, motor starters, contactors, level sensors, and touch-safe fuses

- All controls on the exterior of the panel provide hand or automatic operation

- E-stop, low water pressure indicator, and main disconnect mounted on the face of the panel

- The tank is constructed of rugged 3/16” 304 stainless steel and glass blasted to a uniform finish.

- A grated 3-step fiberglass staircase allows the operator to pour polymer into the hopper comfortably

- The frame is integrated into tank side beams to reinforce tank integrity

- Removable pump skid for simple servicing

- Frame elevated on 5-½” legs

- Fork slots for ease of movement

Dry Polymer Screw Feeder

- Variable speed AC motor and gearbox turning a 1.5” solid shaft stainless steel auger through a stainless steel dispersion tube

- Greasable bearing and stainless steel guard with sight window

- Stainless steel flexible coupling with quick disconnect snap ring

Dry Polymer Wetting System

- Stainless steel conical wetting bowl creates a cyclone into which polymer is metered

- Polymer is optimally hydrated as it enters the tank

- Ball valves allow for adjustment of flow into the wetting bowl

- Water/Polymer solution drops directly into the tank

- Venturi under the water surface further mixes solution in the make-down chamber

- Multiple tank-mounted venturis provide additional mixing

- 2” Y-strainer catches any large particles in the water supply line

- 2” line plumbed to a 5 HP booster pump

- 2” solenoid valve supplies water flow to valves, wetting funnel, and venturis

- Magnetic flow meter prevents batching in the event of a loss of water

- Pressure gauge mounted in piping

Polymer Injection Pump

- One progressive cavity pump is mounted integrally to the unit

- Standard 1 HP polymer pump rated for 0 to 12 GPM (7.9 GPM of fully activated solution)

- Stainless steel guard with sight window

- Stainless steel flexible coupling with quick disconnect snap ring

- Shut off valve from tank to pump provides for easy servicing

- Built-in additional polymer pump port with pre-run wire allows for a second polymer pump

Mix Tank Agitator

- 1-½ HP motor turns a right angle gear reducer with a nickel-plated bore

- 1” stainless steel shaft driving one 14” hydrofoil

- Foot bearing for vibration-free operation

- The shaft is dimpled, and props are anchored with stainless steel bolts, eliminating the possibility of prop slippage

Polymer Tank

- 3/16” Stainless Steel construction

- 817-gallon capacity

- Level sensors provide automatic batching

- 2” cross-over valve between mixing and pull down chambers also serve as floor drains

- Stainless Steel internal weir and baffle walls

Dimensions:

- 5’(W) x 11’2”(L) x 7’2”(H)

Field Requirements

- Single point electrical hook up, 460 volts, 3 phase, 60 Hz standard

- 2” single point clean water hook-up (30 – 60 psi)

- ¾” or greater polymer discharge line

Optional Features

- Low Polymer Sensor

- Allen Bradley PLC & HMI

- Remote Polymer Pump Speed Signal

- AutoFloc Probe and Messenger

- Multi-gang manifold allows polymer solution pumped to several locations

- Additional polymer pumps

- Customer specified components or voltages

Note:

This system is factory set to make-down a .25% polymer solution strength. This can be field adjusted to anywhere between 0.1% to 0.35%. The maximum polymer solution flowrate the system can provide while maintaining the recommended one hour of aging/activation time is 7.9 GPM. The system is assembled, pre-wired, and tested at the factory. Typical installation/start-up time is 1 to 2 hours.

The Model 800SSL is a dry and liquid polymer make-down and injection system. It can pump 12.6 GPM of fully activated polymer solution (15.76 lbs/hr of dry polymer is consumed if making .25% solution strength).

Optimal For:

- Larger flocculant consumers

- Rapid separation of solids from water

- Flocking solids in clarifiers, thickeners, and settling ponds

- Freeing up land by eliminating all but one settling pond

- Greatly reducing the time and cost of cleaning out settling ponds

- Thickening solids going to centrifuges, presses, gravity belts, or other dewatering devices

Equipment Functions:

- Accurately meters, mixes, and ages dry chemical and water, creating a liquid solution

- Produces a uniform solution without the formation of “fish-eyes”

- Administers a site-specific solution at an adjustable-rate

Features:

- Fully automatic, continuous batching operation

- Easily installed and often operational within one hour of arrival

- Extremely rugged industrial design

- Minimal operator attention required

- Can make down either dry cationic or anionic polymers

- Single tank design with internal baffles and weir ensure proper mixing and aging of polymer

- Integrated low water flow protection

- The service-friendly design includes quick disconnect couplings, elevated frame, removable pump skid, anti-seized stainless steel fasteners, and quick-disconnect hoses.

Automatic Control Panel

- NEMA 4 enclosure

- Hand/Off/Auto switches and relays control the automatic sequencing of the process

- 480-volt motors with 110-volt logic and controls

- Standard systems come equipped with three Variable Frequency Drives (VFDs)

- The first VFD controls a 1/2 hp stainless steel volumetric dry polymer feeder that is tied to the flow of dilution water into the polymer system (measured by IFM magnetic flow meter). This ensures a consistent solution strength is maintained

- The second VFD controls a 2hp electric mixer with a gear reducer to power the prop mixer in the mixing chamber

- The third VFD controls the rate at which the polymer pump (0-20 GPM standard, 40 psi max discharge pressure) sends an aged solution to process. This VFD can respond to a 4-20mA input signal in the event of an AutoFloc dosing system being in use

- Complete with breakers, motor starters, contactors, level sensors, and touch-safe fuses

- All controls on the exterior of the panel provide hand or automatic operation

- E-stop, low water pressure indicator, and main disconnect mounted on the face of the panel

Framework

- The tank is constructed of rugged 3/16” 304 stainless steel and glass blasted to a uniform finish

- A grated 4-step fiberglass staircase allows the operator to pour polymer into the hopper comfortably

- The frame is integrated into tank side beams to reinforce tank integrity

- Removable pump skid for simple servicing

- Frame elevated on 5-½” legs

- Fork slots for ease of movement

Dry Polymer Screw Feeder

- Variable speed AC motor and gearbox turning a 1.5” solid shaft stainless steel auger through a stainless steel dispersion tube

- Greaseable bearing and stainless steel guard with sight window

- Stainless steel flexible coupling with quick disconnect snap ring

Dry Polymer Wetting System

- Stainless steel conical wetting bowl creates a cyclone into which polymer is metered

- Polymer is optimally hydrated as it enters the tank

- Ball valves allow for adjustment of flow into the wetting bowl

- Water/Polymer solution drops directly into the tank

- Venturi under the water surface further mixes solution in the make-down chamber

- Multiple tank-mounted venturis provide additional mixing

Water Supply

- 2” Y-strainer catches any large particles in the water supply line

- 2” line plumbed to a 5 HP booster pump

- 2” solenoid valve supplies water flow to valves, wetting funnel, and venturis

- Magnetic flow meter prevents batching in the event of a loss of water

- Pressure gauge mounted in the piping

Polymer Injection Pump

- One progressive cavity pump is mounted integrally to the unit

- Standard 1-½ HP polymer pump rated for 0 to 20 GPM (12.6 GPM of fully activated polymer solution)

- Stainless steel guard with sight window

- Stainless steel flexible coupling with quick disconnect snap ring

- Shut off valve from tank to pump provides for easy servicing

- Built-in additional polymer pump port with pre-run wire allows for a second polymer pump

Mix Tank Agitator

- 2 HP motor turns a right angle gear reducer with a nickel-plated bore

- 1” stainless steel shaft driving one 14” hydrofoil

- Foot bearing for vibration-free operation

- The shaft is dimpled, and props are anchored with stainless steel bolts, eliminating the possibility of prop slippage

Polymer Tank

- 3/16” Stainless Steel construction

- 1600-gallon capacity

- Level sensors provide automatic batching

- 2” cross-over valve between mixing and pull down chambers also serves as floor drains

- Stainless Steel internal weir and baffle walls

Dimensions:

- 6’(W) x 15’10”(L) x 7’9”(H)

Field Requirements

- Single point electrical hook up, 460 volts, 3 phase, 60 Hz standard

- 2” single point clean water hook-up (30 – 60 psi)

- ¾” or greater polymer discharge line

Optional Features

- Low Polymer Sensor

- Allen Bradley PLC & HMI

- Remote Polymer Pump Speed Signal

- AutoFloc Probe and Messenger

- Multi-gang manifold allows polymer solution pumped to several locations

- Additional polymer pumps

- Customer specified components or voltages

Note:

This system is factory set to make-down polymer to a solution strength of .25%. This can be field adjusted to anywhere between 0.1% to 0.35%. The maximum polymer solution flowrate the system can provide while maintaining the recommended one hour of aging/activation time is 12.6 GPM. The system is assembled, pre-wired, and tested at the factory. Typical installation/start-up time is 1 to 2 hours.

The Model 3300SSL is a dry and liquid polymer make-down and injection system. This system is fully automatic and reliable. The M3300SSL can deliver up to 187 pounds per hour of dry polymer, with a 40-minute mixing and aging time.

Optimal For:

- Rapid separation of solids from water

- Flocking solids in clarifiers and thickeners

- Thickening solids going to centrifuges, presses, gravity belts, or other dewatering devices

Standard Features:

- Modular Design for easy unloading and hook-up

- Solution without the formulation of “fish-eyes.”

- Stainless Steel Big Bag pan accepts 1650 pound Big Bags

- Variable speed screw feeder with solid shaft auger

- Low water pressure protection

- Fully automatic operation

- Two progressive cavity polymer disbursement pumps – AC variable speed pump drives – Maximum pump delivery is 50 GPM per pump

- Two 3,000 or 1,500-gallon fiberglass tanks with 5hp mixers turning two stainless steel props

- 3” square steel framework painted with Aliphatic Urethane Epoxy paint, which yields a high, chemically resistant finish that fades little under UV rays

- Two-tank design with a pneumatic 3-way valve assures separate mixing and aging of polymer

- Menu-driven Allen Bradley Panel View Display controls the PLC – Hand/Off/Auto switches provide manual or automatic sequencing

- Air Compressor

Utilities:

- One point electrical hook-up, 460/230 volt 3-phase

- One point clean water hook-up, 3” line at 25 – 80 psi

- Additional field wiring and plumbing are done on-site by Clearwater Industries

Dimensions:

- Framework and Tanks, as per drawings

- Approximate shipping weight 4,000 lbs

Optional Features:

- 4-20mA Polymer Pump drive to accept the external signal

- Remote Speed Pot with 50’ or 100’ of cable

- Automatic Dosage Control hardware and logic in the PLC

- Polymer injection pumps are available in 25, 50, and 125 gallons per minute delivery

- Hand/Off/Auto switches instead of the Panel View Display