Clearwater Industries manufactures DAF systems, also known as dissolved air flotation clarifiers, for industrial wastewater treatment. Through our partnership with SigmaDAF Clarifiers, we are committed to delivering cutting-edge DAF solutions to the North American market.

Dissolved Air Flotation (DAF) clarifier systems are advanced separators that effectively treat industrial wastewater by removing suspended solids, oils, and fats along with associated pollutants. Utilizing dissolved air in the form of microbubbles (30-50 microns), our systems lift solids to the surface, where skimmers remove them. This process results in the discharge of clarified effluent.

Our standard DAF clarifiers are manufactured with 304SS and are available in 316SS, polypropylene, and other materials upon client request. They are easy to operate, fully automated, and have a quick start-up procedure.

Our DAF models and sizes cover a wide range of flowrates:

- DAF FPAC (15 – 880 gpm)

- DAF FPBC (44 – 1100 gpm)

- DAF FPHF (1320 – 4400 gpm)

- Compact DAF (15 – 400 gpm, plug-and-play)

Would you like to learn if a DAF system is the right fit for your application? Contact us and our team will work with you to find the right solution.

DAF SYSTEM PERFORMANCE

When it comes to pollutant removal, the results achieved by our DAF systems are the following:

| COD > 75% |

| BOD5 > 75% |

| Total Suspended Solids > 95% |

| Turbidity > 95% |

| Total Phosphorus > 90% |

| Total Nitrogen > 50% |

| Oils & Fats > 95% |

DAF technology should be paired with proper chemical coagulation and flocculation treatments to ensure optimal performance. Efficient chemical conditioning increases the solids’ size and ability to be contacted by the microbubbles. The chemical treatment process can be achieved by serpentine flocculator mix tubes or chemical mix tanks, which Clearwater provides.

After chemical conditioning, the flocculated solids flow into the DAF clarifier, where they’re captured by microbubbles and floated to the water’s surface. A paddle skimmer system then scrapes the floated solids and removes them from the clarifier. Heavier solids settle in the collection zone at the bottom of the clarifier and are removed with an auger.

OUR DISSOLVED AIR FLOTATION (DAF) SYSTEMS

Standard Features:

- 304SS DAF tank and frame

- Dissolved Air Generation System

- Pneumatic panel single-point air connection

- Recirculation pump

- Dissolved air distribution manifold

- Floated sludge skimmer system

- Settled solids shaftless auger* and pneumatic discharge valve

- *Shafltess auger not included in systems with a hydraulic capacity <66 gpm.

- HMI touchscreen control panel

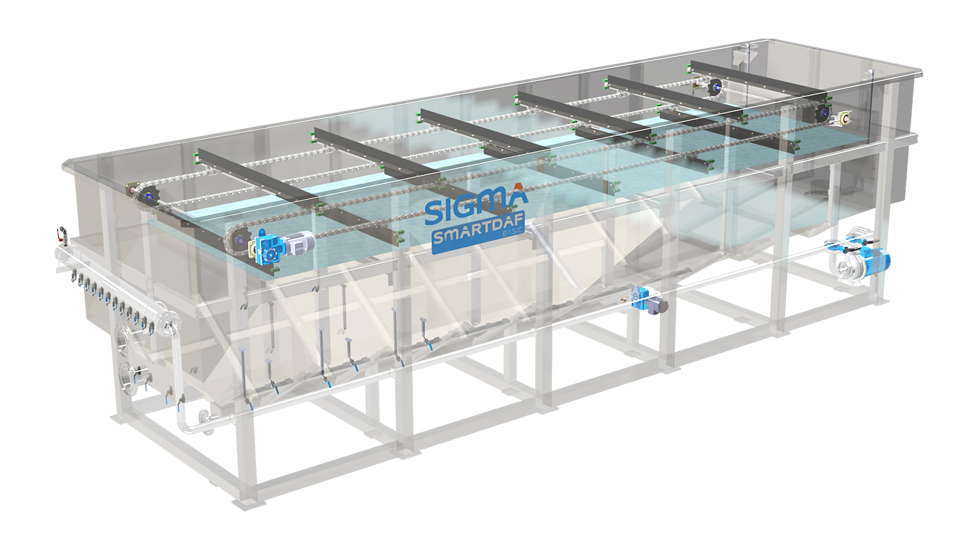

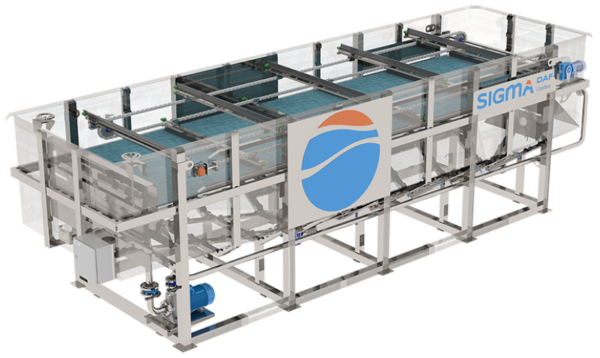

DAF FPAC

The DAF FPAC flotation equipment is a clarification system designed to treat small-to-medium flow rates with very high solids loads (TSS, FOG). The FPAC model is a low-profile cross-flow separator with a large free surface area for floated solids accumulation.

- Capacity: 15-880 gpm

- Achieve sludge with a dry solids content 3 to 4 times higher than a conventional system

- Large surface area for floating sludge accumulation (8 lbs of dry matter treated per sq ft)

- Floated and settled sludge discharge

Features:

- Cross-flow system

- Static thickener

- Single movement separator rotates against the hydraulic flow to minimize the skimming distance and eliminate solids carry-over

- Sludge that settles to the bottom of the system is retained, concentrated, and partially dewatered with the shaftless auger system. The settled sludge is transported to the central discharge point and removed through an automatic pneumatic valve. The discharge cycle has a self-cleaning effect and any particle adhered to the DAF tank walls releases and discharges with the rest of the waste.

- Low maintenance

Industrial Applications:

- Sludge thickener

- Slaughterhouse

- Meat processing

- Fish processing

- Fruit & vegetable processing

- Meal & food processing

- Drink production

- Rendering plants

- Textile production

- Pulp and paper industry

- Increase FBR performance

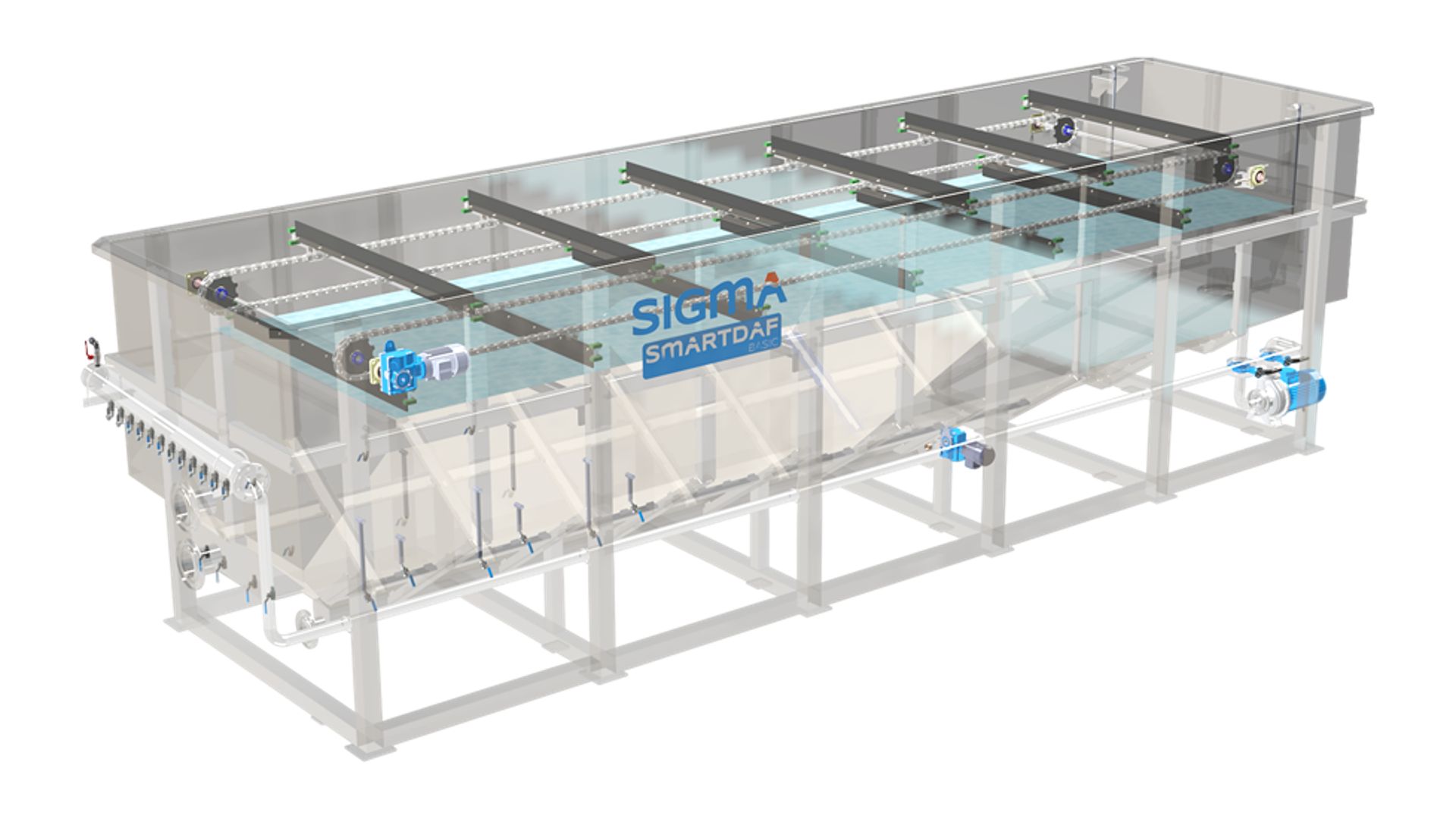

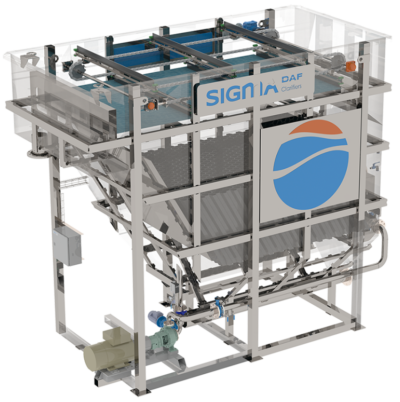

DAF FPBC

The DAF FPBC flotation system is a high-profile separator designed to treat wastewater with low-to-medium solids loads, even those with low buoyancy particles.

The FPBC DAF system is manufactured with lamella pack technology to reduce water flow velocity and obtain maximum separation efficiency. This makes the FPBC model one of the market’s most efficient dissolved air flotation clarifiers.

- Capacity: 44-1,100 gpm

- Achieve sludge with a dry solids content 3 to 4 times higher than a conventional system

- Inclined plate pack increases surface area for solids separation

- Floated and settled sludge discharge

Features:

- Counter-current flow principle achieved through an inclined plate pack

- Plate pack technology increases separation efficiency for highly contaminated water

- Single movement separator rotates against the hydraulic flow to minimize the skimming distance and eliminate solids carry-over

- Sludge that settles to the bottom of the system is retained, concentrated, and partially dewatered with the shaftless auger system. The settled sludge is transported to the central discharge point and removed through an automatic pneumatic valve. The discharge cycle has a self-cleaning effect and any particle adhered to the DAF tank walls releases and discharges with the rest of the waste.

- Low maintenance

Industrial Applications:

- Power & energy industries

- Slaughterhouse

- Meat processing

- Fish processing

- Fruit & vegetable processing

- Meal & food processing

- Drink production

- Petrochemical industry

- Textile production

- Pulp and paper industry

- MBBR treatment

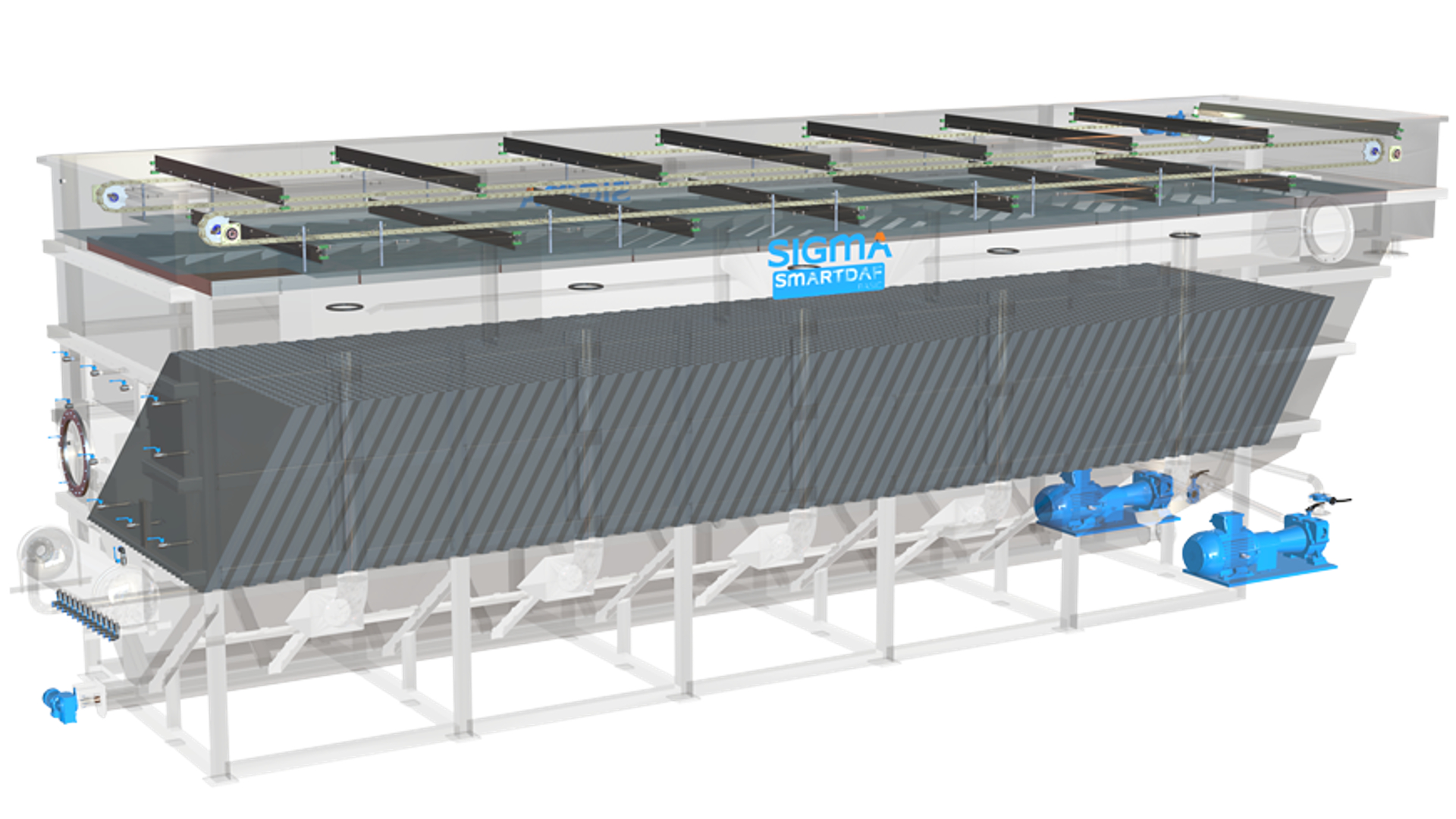

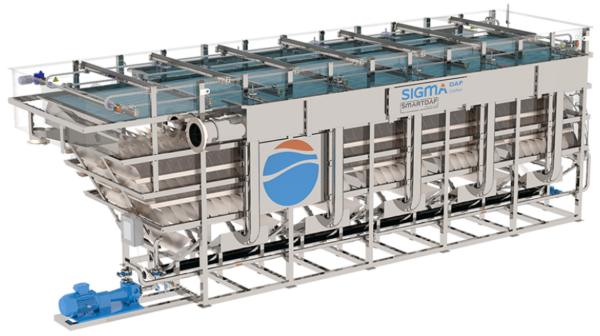

DAF FPHF

The DAF FPHF is a separation system designed to treat high wastewater flows with low-to-large solids loads. The FPHF DAF model represents an improvement over the existing lamella plate technologies by combining cross-flow and countercurrent flow for optimized separation.

- Capacity: 1,320-4,400 gpm

- Sludge with a dry solids content 3 to 4 times higher than a conventional system

- Inclined plate pack increases surface area for solids removal

- Floated and settled sludge discharge

Features:

- The design features plate pack technology and combines cross-flow and countercurrent flow to increase separation efficiency.

- Sludge that settles to the bottom of the system is retained, concentrated, and partially dewatered with the shaftless auger system. The settled sludge is transported to the central discharge point and removed through an automatic pneumatic valve. The discharge cycle has a self-cleaning effect and any particle adhered to the DAF tank walls releases and discharges with the rest of the waste.

- Low maintenance

Industrial Applications:

- Power & energy industries

- Oil refineries

- Petrochemical industry

- Slaughterhouse

- Food processing plants

- Dairy industry

- Manure processing

- Pulp and paper industries

- MBBR Treatment

- Increase FBR performance

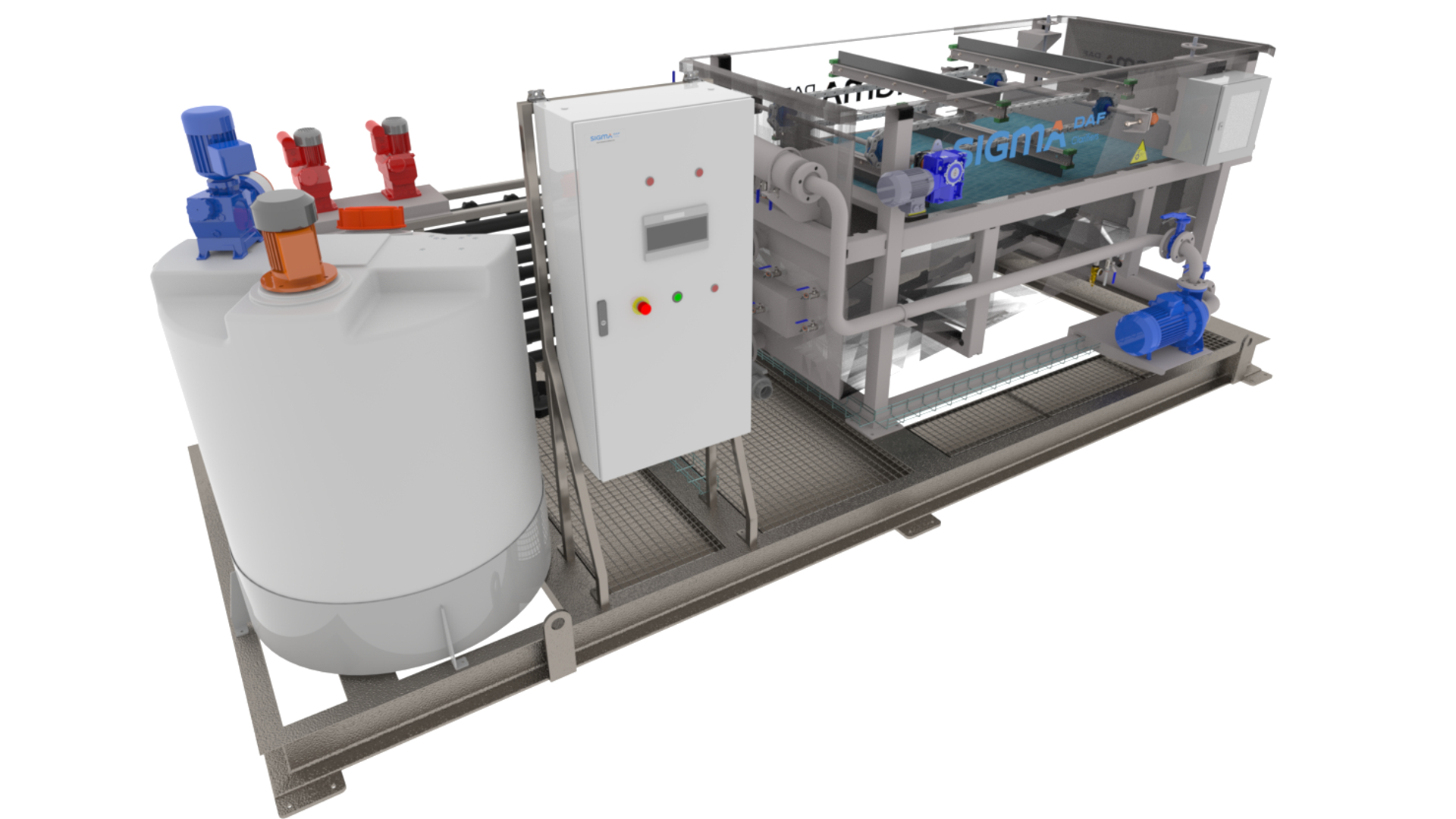

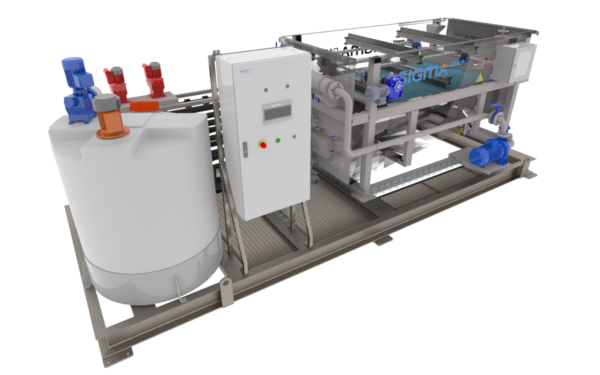

COMPACT DAF

The COMPACT DAF is a pre-assembled turnkey system with chemical conditioning equipment, a DAF clarifier, sensors, instruments, and a control panel. It is robust, flexible, efficient, and easy to operate.

The plug-and-play system allows for easy installation and integration. Operation is easy with a PLC control screen, allowing the operator to adjust the chemical dosing pumps, skimmer speed, and sludge discharge.

The COMPACT DAF equipment has a high removal performance of organic load, solids, oils and fats, and other wastewater pollutants. Flows of 66 GPM or less are managed with a single skid design, while flows larger than 66 GPM are treated with a modular two-skid system.

Benefits

- Plug & Play solution

- Maximum reliability and durability

- Constant effluent quality

- High pollutant removal efficiency

- Easy to operate

- Quick Start-up

- Portable. Capable of installation in containers or on platforms

- Low maintenance requirements

- No civil work needed

Compact DAF Includes:

- DAF consists of a rectangular tank, skimmer, settled sludge extraction valve, air supply valves, pneumatic panel, and recirculation pump

- Flocculator Tubes: In-line coagulation-flocculation system

- Coagulant dosing pump

- Caustic soda dosing pump

- Polymer flocculant dosing pump

- Polymer flocculant preparation unit

- pH sensor and flow meter

- Sludge pump and levels

- Skid-type platform

- State-of-the-art electrical control panel – Fully intuitive and user-friendly interface

We design and manufacture the Compact DAF system to meet the discharge standards for your specific effluent and industry.

INDUSTRIES AND APPLICATIONS

As an experienced DAF system manufacturer, we serve various industries. The scope of applications of our DAF systems is virtually unlimited, but here are some of the most common industries that we have worked with:

This knowledge and expertise allow us to provide our customers with the most efficient technologies and solutions for the treatment of the wastewater generated in their production processes.

VIDEOS

CASE STUDIES

SIGMADAF USA

SigmaDAF USA is a joint venture between Sigmadaf Clarifiers and Clearwater Industries that supplies DAF systems to the North American market. This partnership allows Clearwater Industries to manufacture Sigmadaf’s DAF technology for North American applications. Located in Brown Deer, WI, Clearwater Industries has manufactured equipment and provided solutions for industrial wastewater treatment since 1996.

Established in 1994, Sigmadaf Clarifiers has completed over 800 projects in over 25 countries. With a global presence, Sigmadaf has completed installations from simple assembly projects to complex infrastructures to meet the world’s strictest discharge requirements.

CONTACT US

Tell us about your challenges. Our team will contact you to discuss a tailored solution based on our experience.