Year: 2011

Project Location: Beiersdorf Manufacturing Tres Cantos S.L. – Madrid.

Objectives: Design and install a wastewater treatment plant to obtain high-quality water for reuse. Treatment of the sludge generated in the wastewater treatment plant.

Installed Equipment: Oils and fats separator SIGMACELL ACAF; Equalization tank with aeration by diffusers AQUA-JET; Coagulation, flocculation, and pH adjustment system (includes reagent preparation tanks and reaction tanks); Flotation system SIGMA DAF FPBC-PWF; Biological reactor MBR with an external module of ultrafiltration membranes; Aerobic sludge digestion reactor; Sludge dewatering with centrifuge

Capacity: 110 GPM, with a capacity for 165 GPM for future manufacturing plant expansion.

Wastewater Characteristics

| COD | BOD5 | TSS | Oil & Fat |

|---|---|---|---|

| 11600 mg/L | 3700 mg/L | 1060 mg/L | 2000 mg/L |

Physical-Chemical Treatment (CAF & DAF) Removal Perforamce

| COD | BOD5 | TSS | Oil & Fat |

|---|---|---|---|

| 44% | 19% | 81% | 95% |

Biological MBR Treatment Removal Performance

| COD | BOD5 | TSS |

|---|---|---|

| 96% | 95% | 95% |

Total Plant Removal Performance

| COD | BOD5 | TSS | Oil & Fat |

|---|---|---|---|

| 98% | 96% | 99% | 95% |

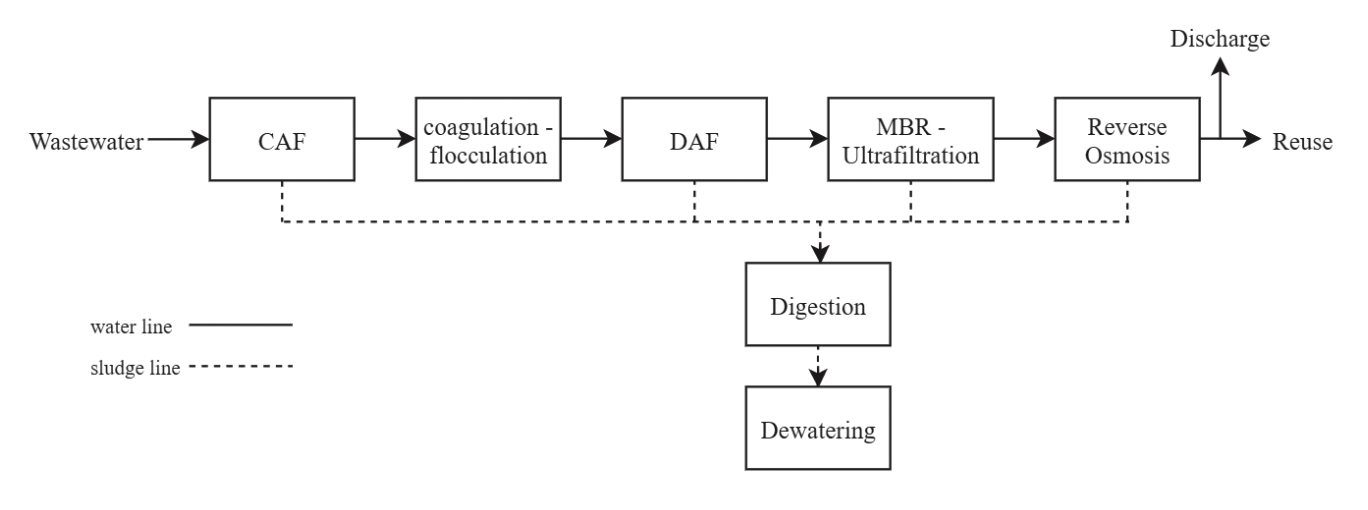

Wastewater from the cosmetic industry is characterized by a high content of suspended solids, COD, oils, and fats. Given the tightening of discharge limits and the increasing need for water reuse, more and more intensive and efficient treatment processes are being applied that include advanced technologies to meet the quality requirements of reuse. In the case of Beiersdorf Manufacturing Tres Cantos S.L., SIGMA designed and built a complete wastewater treatment plant based on the physical-chemical process (CAF, coagulation-flocculation, DAF) followed by a biological MBR process.

Fats and oils are removed in the SIGMACELL ACAF unit. The water is then homogenized and subjected to a carefully studied coagulation-flocculation process; for this, jar tests were carried out to determine the type and optimal dosage of a coagulant (PAC with polyamine) and flocculant (cationic polymer). The flocculated solids are separated in the SIGMADAF FPBC-PWF unit, which obtains high-quality clarification. For the elimination of biodegradable organic matter, an MBR (Membrane Bio-Reactor) biological treatment system is installed with advanced ultrafiltration membrane technology. The MBR treatment provides clarified water that is recirculated and reused in the production process of the cosmetic plant.

Oil and Fat Removal in the SIGMA ACAF Unit

- Simple operation – does not contain complex mechanical equipment and does not require manual intervention.

- Wide range of treatment capacity: SIGMA ACAF treats up to 2200 GPM and can be adapted to treat higher flowrates using special systems.

- Excellent results: oil and grease removal in a SIGMA ACAF system can reach up to 99%.

- In addition to the elimination of oils and fats, the units support the rest of the treatment by removing a high percentage of suspended solids.

Total Suspended Solids Removal in the SIGMA DAF Clarifier

- High and constant clarified water quality.

- Quick start-up.

- Minimal sludge production (sludge concentrations of up to 5% – much higher than achieved by conventional settlers).

- Easy to operate with simple, adaptable, and efficient control systems.

- Known technology, flexible to each case and robust.

Aerobic Biological Process MBR with Ultrafiltration Membranes

- Very high organic load reduction (>90% COD and BOD5 removal).

- Very high concentration of BIOMASS inside the reactor: between 6,000 and 12,000 mg/L MLSS.

- Compact and modular plant – simple to operate.

- High resistance to oxidizing agents.

- Very high and constant quality of the water discharged allows for reuse.

- Minimal sludge generation.