Clearwater Industries’ dry polymer make-down systems include a lifetime warranty with the exclusive use of our chemistry. Our standard M-Series dry polymer systems are turnkey and automated to ensure reliable performance. The M-Series units provide a continuous and fully aged polymer solution, automated operation, and require minimal operator attention.

Our standard systems and custom designs can accommodate any polymer consumption, from a few pounds per day to hundreds of pounds per hour.

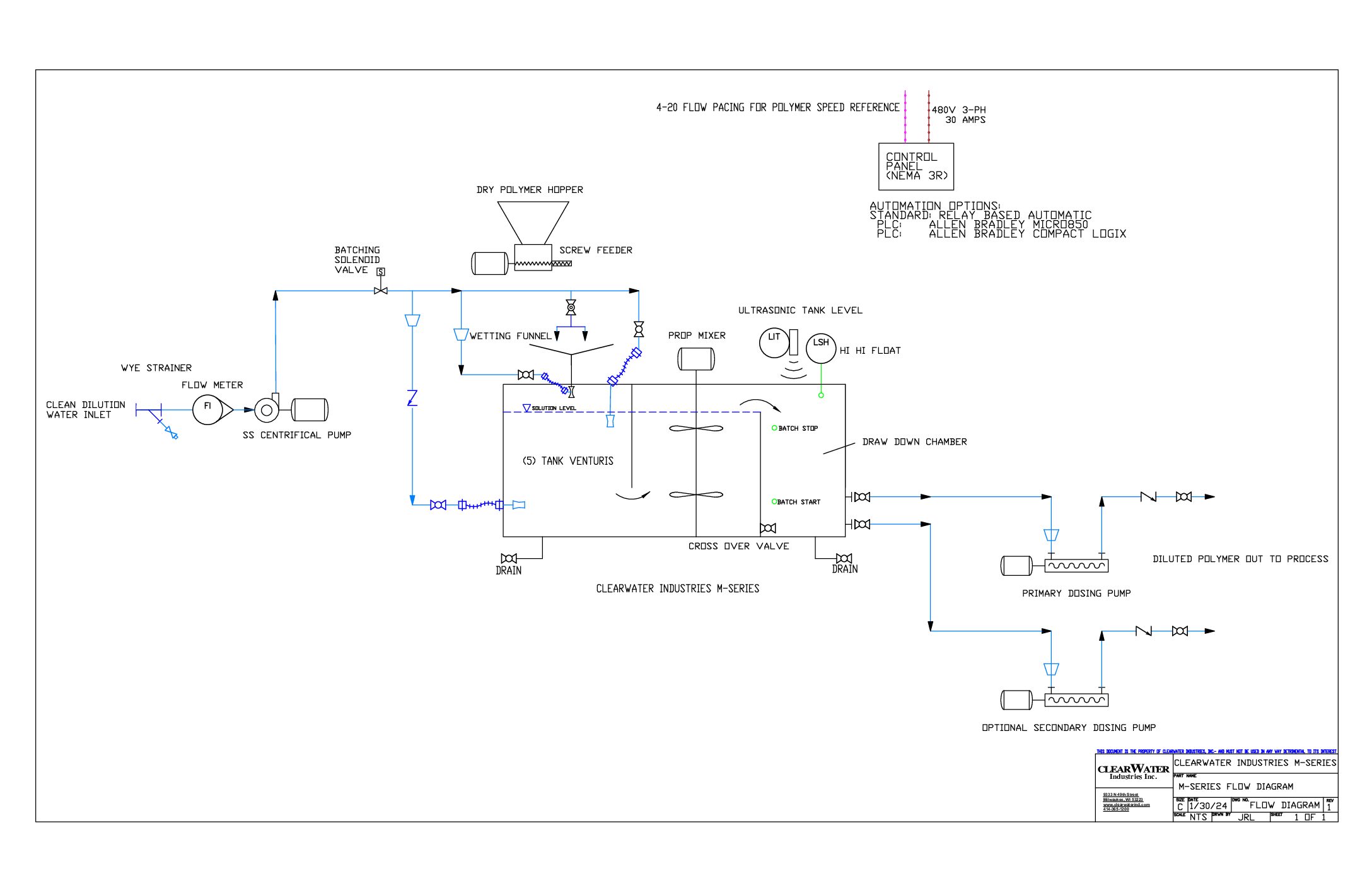

The system fully activates and ages the solution to minimize polymer consumption by featuring a single tank with three chambers. A variable-speed feeder automatically meters dry polymer to maintain a programmed solution strength. Proper polymer-particle wetting plus hydraulic and timed mechanical mixing deliver a uniform polymer solution. You can rely on our systems to accurately activate, age, and dose the polymer solution.

M-SERIES DRY POLYMER MAKE-DOWN SYSTEMS

| Model | Dosing Rate (GPM)* | Age Tank (Gal) | Length (in) | Width (in) | Height (in) | Weight Dry (lbs) | Weight Wet (lbs) | Power |

|---|---|---|---|---|---|---|---|---|

| M300SS | 0 – 5.5 | 495 | 146 | 72 | 82 | 2331 | 7446 | 480V/3Ph/30A |

| M500SS | 0 – 8 | 715 | 167 | 72 | 82 | 2632 | 9450 | 480V/3Ph/30A |

| M800SS | 0 – 12.6 | 1130 | 191 | 72 | 94 | 3333 | 16685 | 480V/3Ph/30A |

| M3000SS | 0 – 25.3 | 2275 | 240 | 89 | 111 | 4667 | 29703 | 480V/3Ph/30A |

| Custom | Any | Any | Any | Any | Any | Any | Any | Any |

*Dosing rate, or solution flow rate, is based on the recommended 90 minutes of aging.

Although typically used to prepare polymer flocculants, we’ve customized units to prepare and dose aluminum sulfate, bentonite clay, lime slaker, powdered activated charcoal, starch, and more.

Standard Features

- 3/16 304SS tank glass blasted to uniform finish with fork slots

- 110 lbs 304SS dry polymer hopper

- Variable speed screw feeder

- Stainless steel conical wetting bowl creates a cyclone of water to ensure proper polymer-particle activation

- Hydraulic venturis mix the polymer in the first chamber

- Agitator with low-impact hydrofoil mechanically mixes the polymer solution in the second chamber

- Flowmeter prevents low-flow batching

- Progressive cavity polymer dosing pump with VFD for 4-20mA control mounted to the system

- 2″ dilution water Y-strainer

- (2) 2″ drain valves

- NEMA 3R control panel enclosure

- Hand/Off/Auto switch controls for automatic or manual control

- 480V motors with 120V logic and controls

Big Bag Options

- 1650-2000 lbs Big Bag supports

- Big Bag Pan & Hopper

- Big Bag Tower

- Big Bag Hoist

- Request our Accessories Brochure to review options like vibrators and low polymer sensors

Optional Features

- 110 lbs sliding top hopper

- 220 lbs 304SS hopper. Hinged or sliding

- 1650 – 2000 lbs Big Bag setup

- PLC Controls

- Additional age tank for high polymer consumption applications

- AutoFloc Dosing System for automated polymer dosing

- Multi-gang manifold for multiple polymer dosing locations

- Additional polymer pumps

- Liquid polymer preparation system integration

Containerized Systems

- 10′, 15′, 20′, & 40′ High Cube Conex Box options

- Double-stacked Conex Boxes fit big bags for high-consumption applications

- Single-point electrical hookup

- HVAC Climate-control

- Spray foam insulated

- LED Lighting

- Man door installed

Contact us and our team will answer your questions and determine the best system for your application.

VIDEOS

OPTIMIZED FOR YOU

Dry polymer systems require smart simplicity for limited operator requirements and efficient polymer preparation. We achieve this with a few standard features on our M-Series line. First, our dry polymer feed systems automatically introduce the polymer granules to maintain a programmed solution strength. The granules are dispersed into a cyclone of water in the wetting bowl, which provides efficient initial activation. Next, the solution experiences high-energy hydraulic mixing to reduce agglomeration. From there, a second low-energy mechanical mixing stage continues to unravel the polymer without breaking the chains throughout the maturation process. Finally, the solution overflows a weir into the “draw down chamber” from which it is pumped to process. The M-Seriers dry polymer make-down system offers precise dosing rate, dilution level, mixing time, and energy control.

Dry polymers are typically the most cost-effective way to use flocculants. They contain 90+% active chemistry, whereas liquid polymers are closer to 30% active. The active chemistry makes dry polymers ideal for liquid-solid separation, sludge dewatering, and potential cost savings.

We offer free jar testing to determine your application’s best polymer, dosing rate, and equipment package. At our lab, we’ll compare a variety of dry and liquid polymers to confirm flocculation efficiency, minimize consumption, and reduce cost. Contact us today for sample shipping instructions and to learn how we tailor a solution to your operation.