Year: 2009

Project Location: Helados Estiu S.A. in Ribarroja, Valencia, Spain.

Objective: Removal of organic load from the pre-treated wastewater for discharge of the effluent to the public water network. Adaptation to future needs and expansion of the plant.

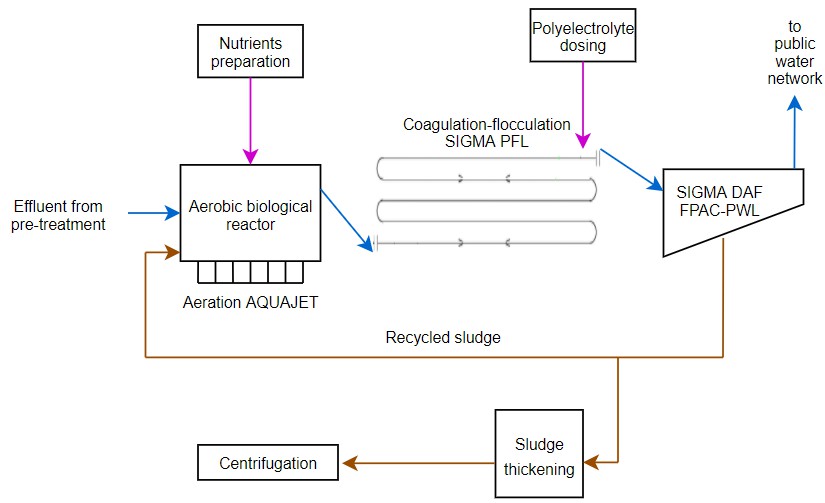

Installed Technologies: Aeration tank for biological treatment; aeration system AQUAJET; coagulation-flocculation in-line system SIGMA PFL flocculator tubes; flotation system SIGMA DAF FPAC-PWL; sludge thickening tank and sludge dewatering with centrifugal decanter; nutrients and chemicals dosing equipment; control and automation systems.

Capacity: 185 GPM

Average Organic Load of the Pre-treated Wastewater

| COD | BOD 5 |

|---|---|

| 4500 mg/L | 2500 mg/L |

Efficiency of the Full Treatment

| COD Removal | Treated Sludge Dry Matter Content |

|---|---|

| >90% | >50% |

Helados ESTIU S.A. is an industry leader in the production of different types of ice cream. Its wastewater at the Ribarroja facilities contains a VERY HIGH MASS LOAD. The facilities already have pre-treatment, but the client wanted to install a biological treatment to eliminate the organic load required for discharge to the general collector.

SIGMA designed and installed an FBR process (flotation bio-reactor) consisting of an aeration reactor where aerobic biological treatment is carried out. The biological process consists of the transformation of the organic matter contained in the wastewater into microbial flocs by adsorption and agglomeration.

Separation of the biomass is done by flocculation and secondary clarification in a DAF clarifier. In this process, biomass flocs are formed and separated by flotation with air micro-bubbles in a DAF FPAC-PWL unit. The special equipment obtains sludge with a dry solids content 3 or 4 times higher than a conventional system.

In the SIGMA DAF FPAC-PWL flotation equipment, clarified water that meets discharge requirements is obtained. Part of the produced sludge is recirculated to the biological reactor to maintain a stable biomass concentration, and the rest is discharged. The addition of a polymer flocculant to the clarification system allows the generation of easily separable biomass flocs in addition to providing a high concentration of biomass inside the reactor. Therefore, this system provides higher performance than other biological systems of suspended biomass.

The SIGMA DAF FPAC-PWL flotation system is a modular system that is easy to expand and has a high capacity to adapt to different biomass concentrations.

SIGMA also installs a complete sludge treatment process: thickening and dewatering in a centrifugal decanter.