Clearwater Industries manufactures dissolved air flotation (DAF) systems for industrial wastewater treatment. Remove FOG, TSS, BOD, COD, and pollutants from your wastewater. Review our DAF clarifiers below or contact us for more information.

Dissolved air flotation (DAF) for industrial wastewater treatment is a water clarification process that uses micro-bubbles to remove impurities and solids. The process is ideal for removing light impurities and solids that tend to float and suspend in liquid.

The DAF process contrasts water treatments focusing on sedimentation to remove settled solids. However, most DAF systems account for some sedimentation and settled sludge removal. We highlight this below.

DAF systems separate solids, oils, greases, and other impurities from water. The clean water can be reused or discharged. DAF systems treat for a variety of goals, including:

- Treatment to meet discharge regulations

- TSS Removal

- Water recovery and reuse

- Pretreatment to reduce loading on downstream biological treatment systems

- COD & BOD reduction

- Polishing of biologically treated effluent

- Sludge thickening

- Pretreatment for desalination plants utilizing reverse osmosis

How Does Dissolved Air Flotation Work?

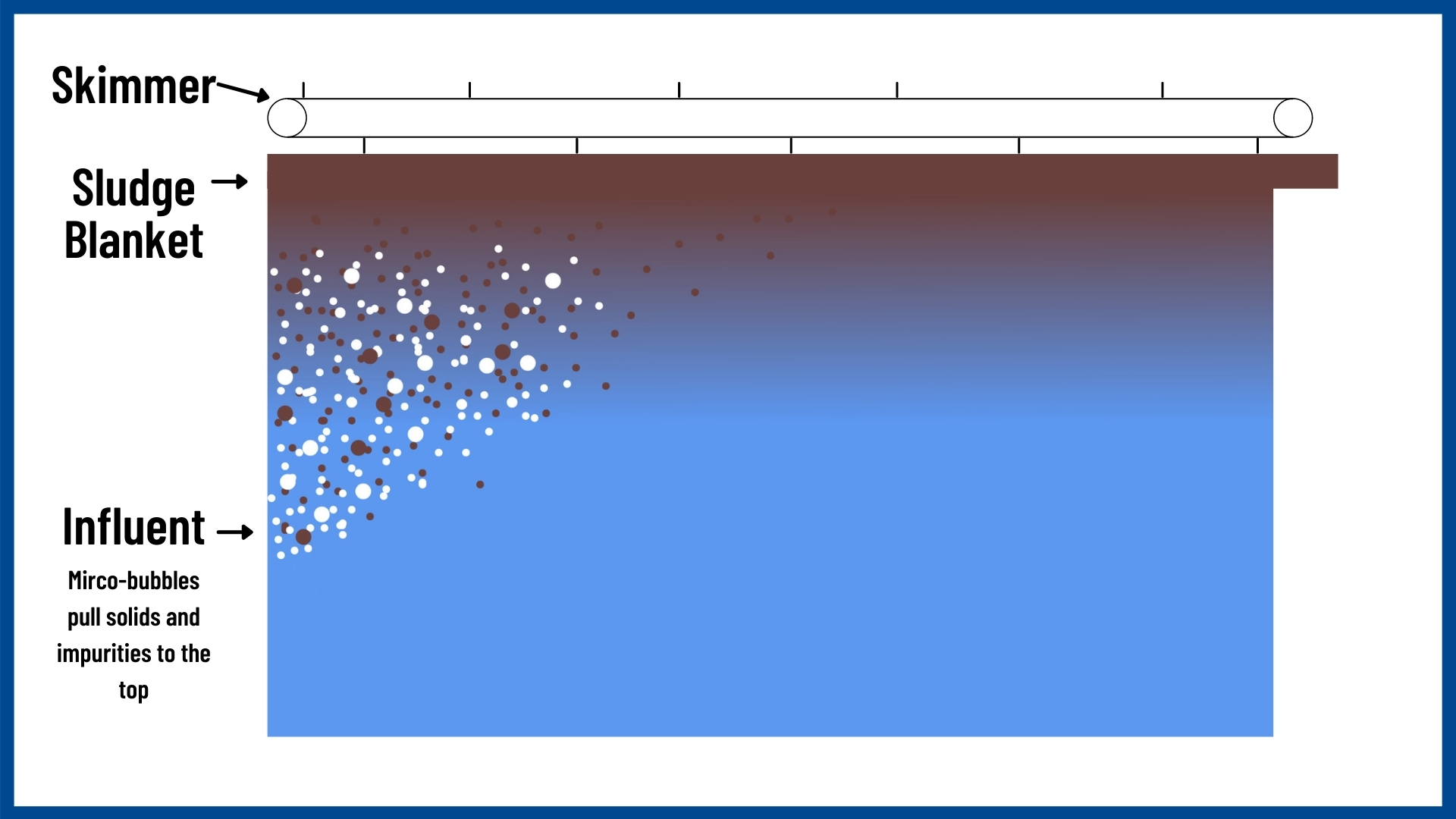

DAF uses micro air bubbles (30-50 micron) that attach to impurities and flocculated particles and float them to the water’s surface. Then, a skimming system removes the sludge to a collection trough, and clean water is recovered.

The clean water can be reused for process or discharged, and some of it is recycled back to the DAF process.

DAF Clarification Steps

First, clean water must be accessible for a DAF system to start. Clean water is necessary because DAF systems pressurize the water and mix it with pressurized air. Under pressure, the air dissolves, and when de-pressured, micro-bubbles form. The micro-bubbles are necessary for the cleaning process.

The first step is to fill the DAF system with clean water. If you fill the DAF unit with wastewater, you’ll likely discharge dirty and non-clarified water for a long time. Plus, you risk damaging the recirculation pump and air saturation system.

Once clean water is in the system, a recirculation pump pulls some of the clarified water to a pressurization-saturation system. Next, the water is pressurized by a pump and mixed with pressurized air. Under this pressure, the air dissolves in the water.

Now, the saturated water flows under pressure to the clarification tank. The pressure is released as the saturated water flows into the tank and micro-bubbles form.

The micro-bubbles attach to the impurities from the incoming wastewater stream and pull them to the tank’s surface. When the solids rise with the aid of micro-bubbles, a floating sludge blanket forms on top of the water within the clarifier.

Next, a skimming system gently removes the sludge from the top of the water. In the video below, you’ll see the skimmers pull sludge off the top and drop it into a collection trough.

Finally, clarified water is recovered through a supernatant system. Basically, the treated water comes out of a discharge point below the floating sludge and above the settled sludge.

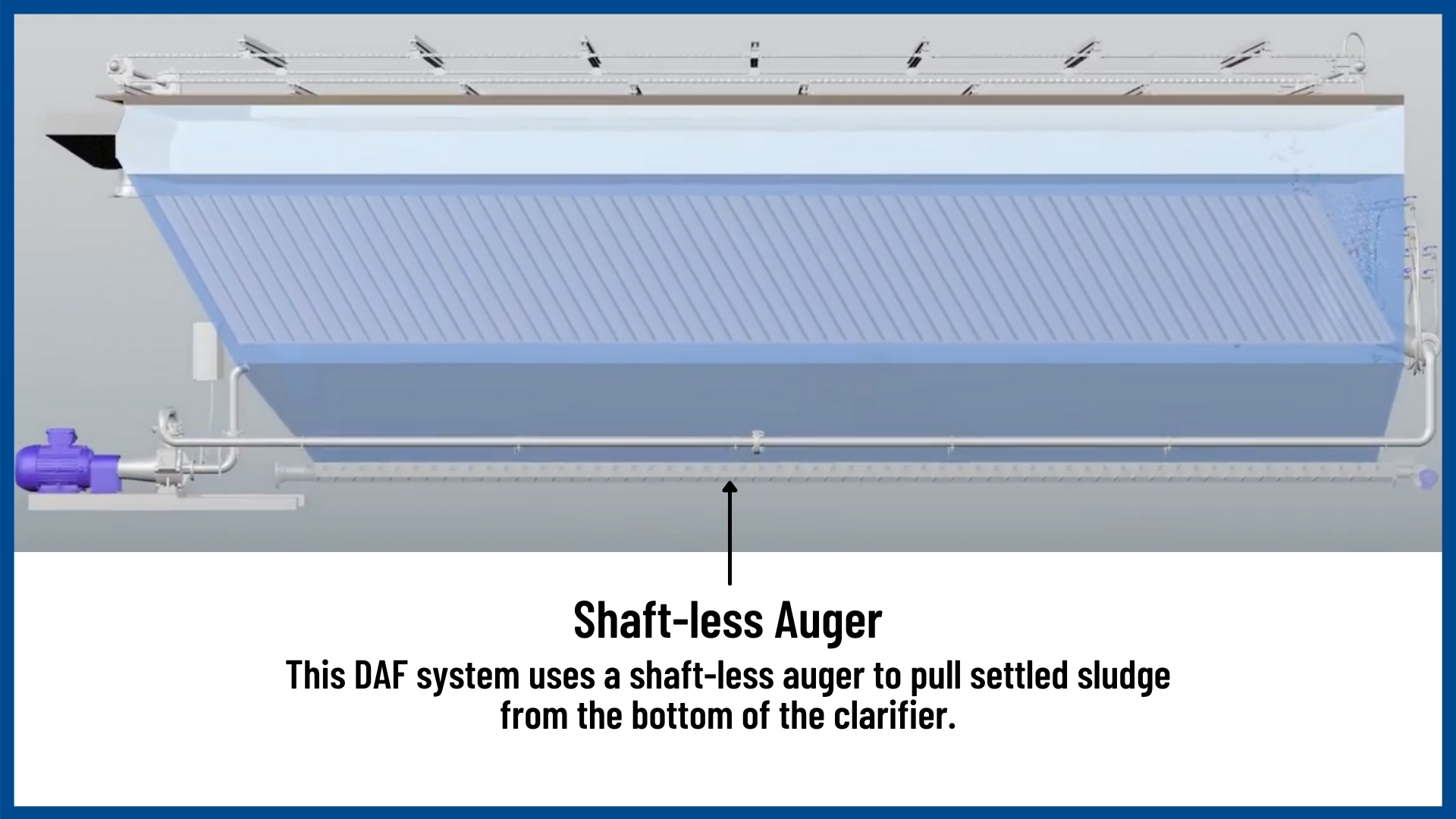

Do DAF Systems Manage Settled Sludge?

Most systems account for and manage settled sludge. DAF systems are ideal for wastewater streams that contain solids that float and settle.

In general, you’ll find most manufacturers include a sediment compartment or basin with a sludge extraction system.

Chemical Treatment with DAF Systems

Coagulants and flocculants are regularly used to chemically condition wastewater before it enters a DAF system. Acids and bases are also used to adjust pH levels.

Like other wastewater clarification methods, coagulation and flocculation increase the efficiency of a DAF system’s solids removal. The chemical condition process also creates a thicker, more dewatered sludge that may need little to no further dewatering.

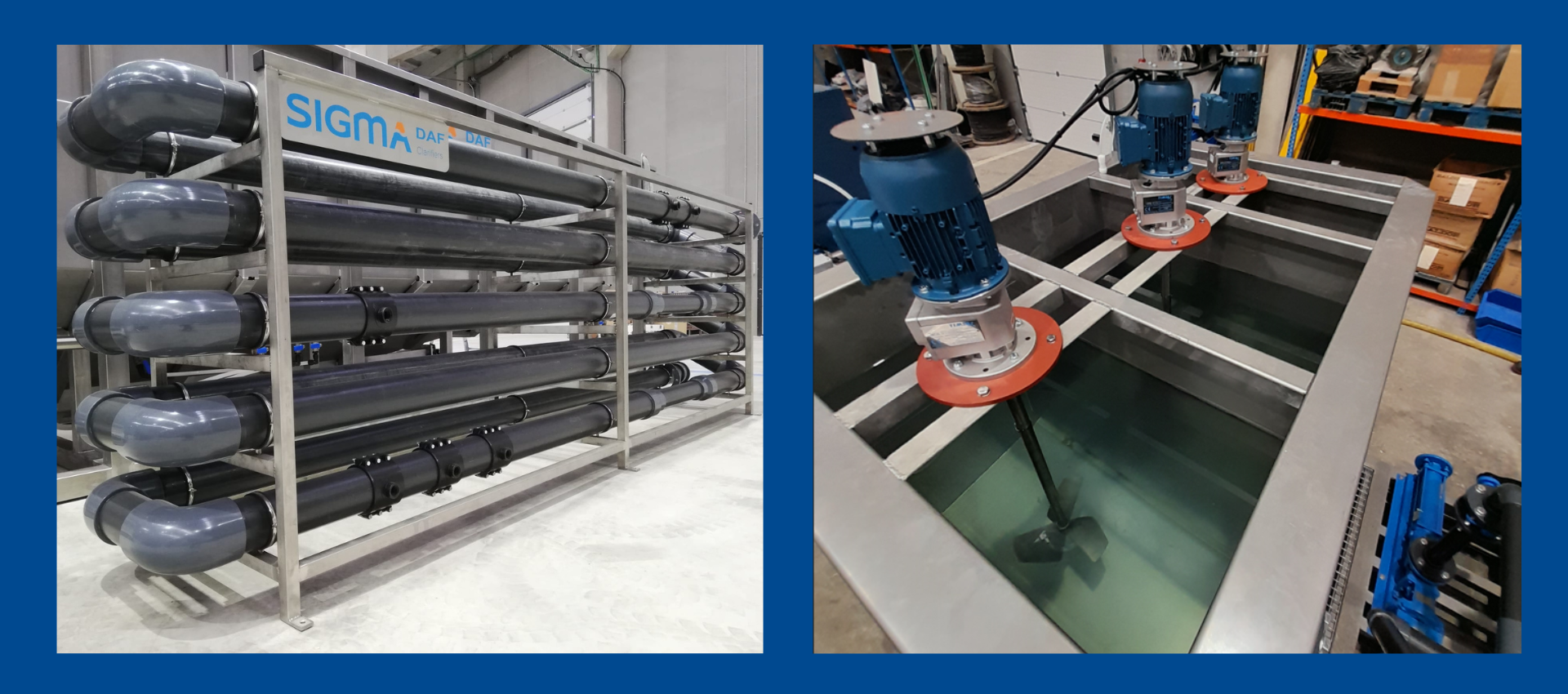

Mixing the chemicals with the wastewater is done with flocculation tubes or chemical mix tanks.

Flocculation tubes are a series of pipes in a serpentine pattern that provide a flash-mixing process of 15-45 seconds. The tubes have dosing locations for a coagulant, pH adjustment, and polymer flocculant. You’ll usually see a pH sensor for monitoring and sample collection valves to check the chemical condition process.

Mix tanks are a series of tanks that use impeller agitators to mix the chemicals with the wastewater for a longer period of time. Some chemicals require extended contact time with the wastewater to change the pH or achieve coagulation and flocculation. The number of tanks used depends on the chemicals required, and you’ll usually see one tank per chemical being introduced. The amount of contact time is variable, and you’ll need to perform jar testing to understand proper mixing time.

What Applications are DAF Clarifiers Used to Treat?

Due to their design and technology, DAF clarifiers can service many industries. Different DAF clarifier designs and models treat water flows with low to high impurity levels. They’re ideal for wastewater streams with oil, grease, and impurities that float or have a low specific gravity.

DAF systems can service but are not limited to the following industries & production processes:

- Oil, Petrochemicals, and Refineries

- Energy Production

- Pharmaceutical & Cosmetics

- Mining, Quarries, and Aggregate Production

- Tunneling & Boring

- Meat & Poultry Processing

- Slaughterhouse Processing

- Fish & Crustacean Processing

- Dairy Industry

- Convenience Food

- Potato Processing

- Fruit Processing

- Vegetable Processing

- Bakeries & Confectionaries

- Brewing (Alcoholic & Non-Alcoholic Production)

- Textile Finishing and Dyeing

- Tannery Production

- Stone Processing

- Tar Sand & Oil Sand

- Heavy Metal Removal

- Industrial & Commercial Laundries

- Pulp & Paper Production

- Algae Removal & Desalination Pretreatment

- Pretreatment for Downstream Biological Treatment Systems

Is a DAF System the Best Way to Treat Your Wastewater?

It’s hard to say without knowing the details of your application. There are many different DAF system designs to treat variable wastewater solids content and flow rates.

We always recommend talking with an application engineer to determine the equipment and solutions for your application. They will want to understand your flow rates, plant operations, and production goals to recommend the best solution for your application.

A DAF Clarifier for Every Flow & Industrial Need

DAF FPAC

The DAF FPAC flotation equipment is a clarification system characterized by a large wastewater flotation area and cross-flow separation. The FPAC is a low-built cross-flow separator with a lot of free surface area for floated solids accumulation.

The FPAC treats small-to-medium flow rates with very high loads of contaminants (impurities, solids).

- Capacity: 20-880 gpm

- Achieve sludge with a dry solids content 3 to 4 times higher than a conventional system

- Large surface area for floating sludge accumulation (8 lbs of dry matter treated per sq ft)

- Floated and settled sludge discharge

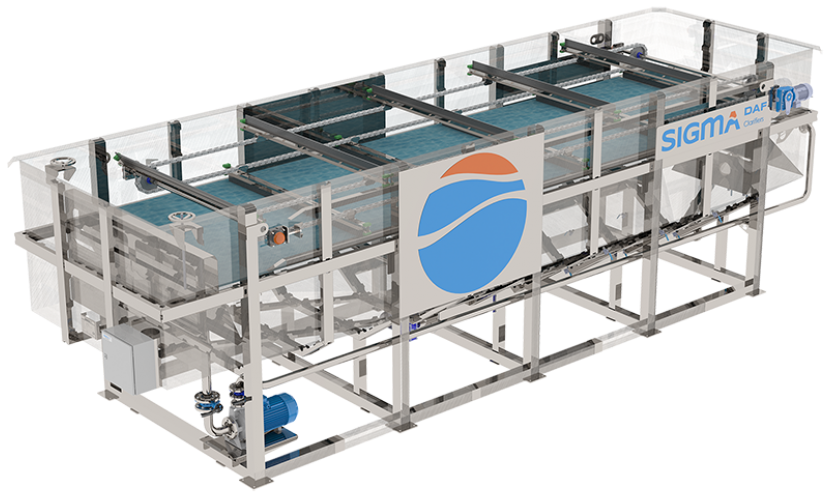

DAF FPBC

The DAF FPBC flotation system is a high-profile separator designed to treat wastewater with low-to-medium loads of contaminants, even those with low buoyancy particles.

Thanks to the application of the plate separating technology, the FPBC DAF system obtains maximum separation efficiency with very low overflow rates. This makes the FPBC model one of the most efficient dissolved air flotation clarifiers in the market.

- Capacity: 44-1,100 gpm

- Achieve sludge with a dry solids content 3 to 4 times higher than a conventional system

- Inclined plate pack increases surface area for solids separation

- Floated and settled sludge discharge

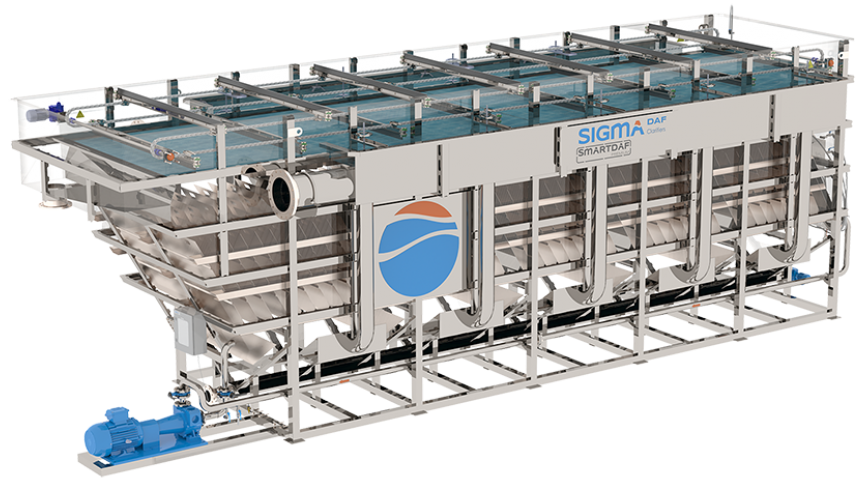

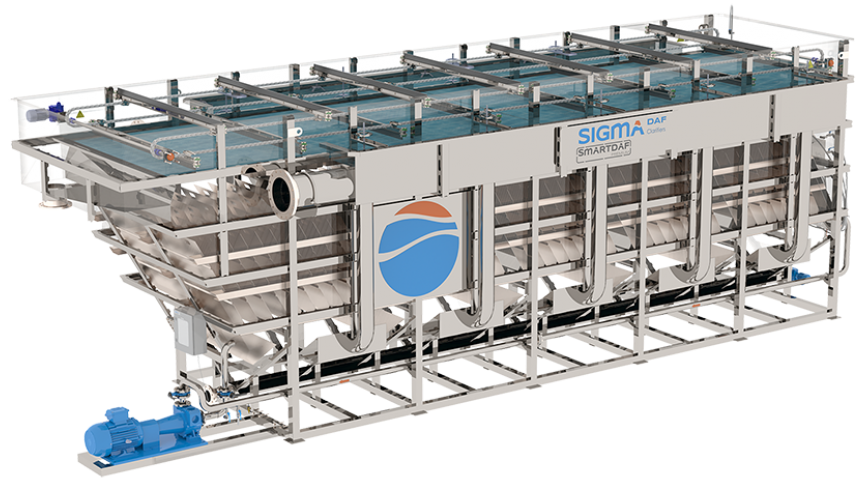

DAF FPHF

The DAF FPHF is a separation system that represents an improvement over the existing lamella plate technologies; it uses a combination of cross-flow and counter-current-flow for optimized separation. The FPHF treats large flows with medium-to-large loads of contaminants (impurities, solids).

- Capacity: 1,320-4,400 gpm

- Sludge with a dry solids content 3 to 4 times higher than a conventional system

- Inclined plate pack increases surface area for solids removal

- Floated and settled sludge discharge

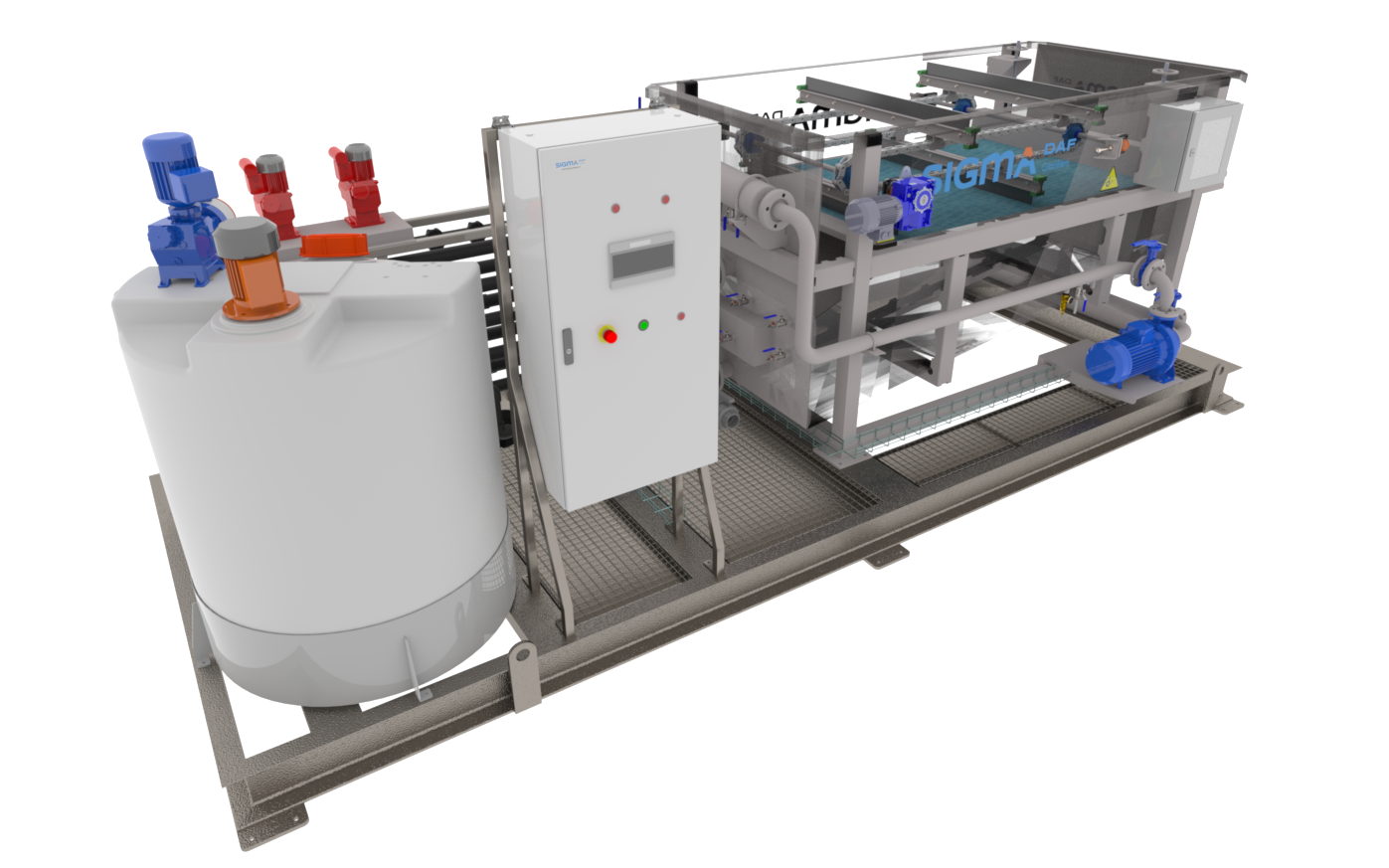

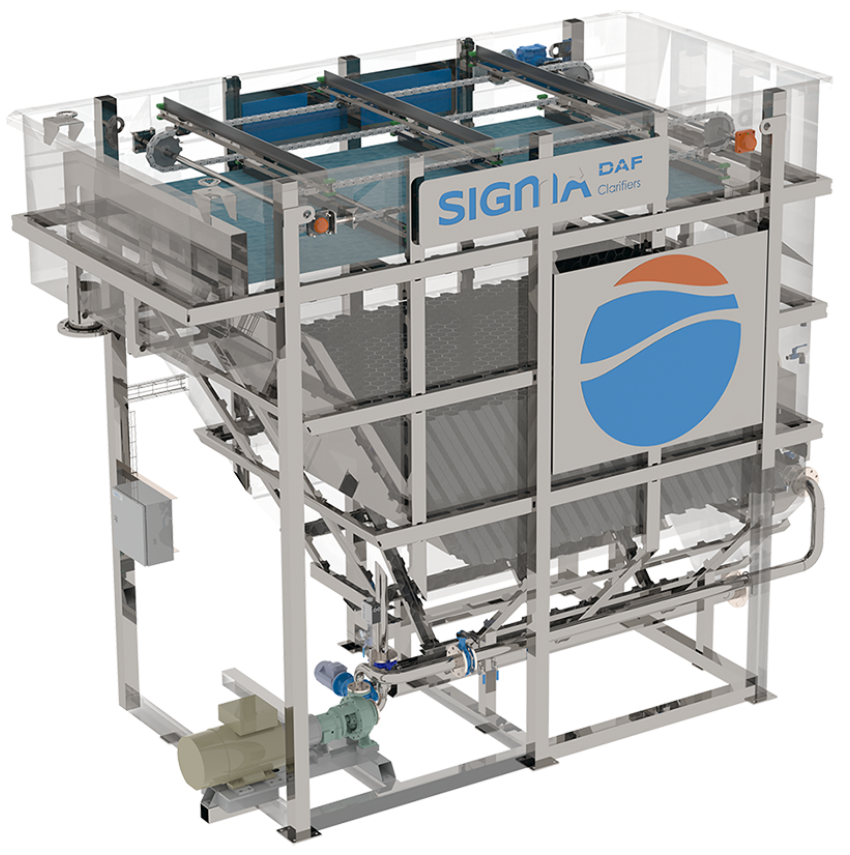

COMPACT DAF

The COMPACT DAF is a pre-assembled turnkey system with chemical conditioning equipment, a DAF clarifier, sensors, instruments, and a control panel. It is robust, flexible, efficient, and easy to operate.

The plug-and-play system allows for easy installation and integration. Operation is easy with a PLC control screen, allowing the operator to adjust the chemical dosing pumps, skimmer speed, and sludge discharge.

The COMPACT DAF equipment has a high removal performance of organic load, solids, oils and fats, and other wastewater pollutants. Flows of 66 GPM or less are managed with a single skid design, while flows larger than 66 GPM are treated with a modular two-skid system.