Cost-effective solution reduces polymer consumption while ensuring uninterrupted operation.

Municipal wastewater treatment plants serving the local community cannot accept shutdowns due to broken equipment. Redundant systems and auxiliary equipment are necessary to support the 24/7 society they serve, as system failures can lead to regulatory violations, environmental impacts, and costly emergency repairs.

In 2022, a municipal wastewater treatment plant in central Florida determined its old dry polymer system needed to be replaced and contacted Clearwater Industries. The aging system had become increasingly unreliable, with frequent dosing inconsistencies and maintenance issues threatening operational continuity. The WWTP manages 2.5 MGD as a primary settling and sludge digestion facility and needed a new dry polymer system for the gravity belt thickeners.

Location: Central Florida

Challenge: Redundant dry polymer make-down systems to avoid client shutdowns. Spatial restrictions.

Treatment: Polymer make-down and dosing to aid in sludge dewatering by gravity belt thickener.

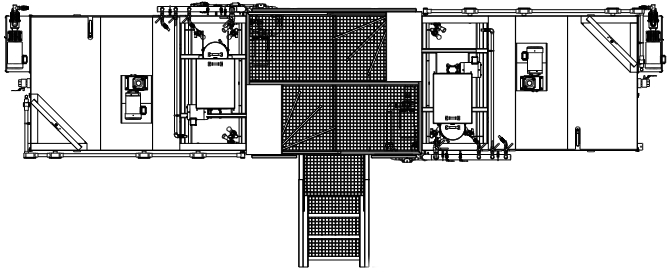

Unit Type: (2) M500SS Dry Polymer Make-Down Systems + Custom Access Platform

Benefits: 100% uptime. Reduced chemical consumption.

Clearwater Industries worked with the client to understand their requirements and goals. The client required:

- Efficient dry polymer make-down for up to 7 GPM of polymer solution – Essential for maintaining optimal sludge thickening performance

- Automatic batching – To reduce operator workload and ensure consistent polymer solution strength

- Complete redundancy – To eliminate single points of failure and allow for maintenance without process interruption

- 300″x117″ available space – Limited installation footprint requiring a compact solution

With this information, Clearwater identified the proper system by customizing our standard M500SS Dry Polymer Make-down System. The modular design allowed Clearwater to smoothly couple two units with a single access platform, providing complete redundancy in the client’s available space.

The M500SS is a turnkey dry polymer system that features a 304 stainless steel tank with three chambers for efficient activation, mixing, and aging of the polymer solution. In-house manufacturing and wet testing, combined with robust TEFC motors and metal dosing pumps, ensure reliability and durability in the demanding wastewater treatment environment.

The system is automated and only requires the operator to ensure dry polymer is in the hopper. A level sensor automates batch sequences, and a consistent solution strength is maintained by flow-pacing the screw feeder with the dilution water flowmeter. Low dilution water flow and low polymer level alarms protect the equipment and notify the operators of potential issues before they affect process performance.

By using our standard and turnkey M-Series Dry Polymer Make-Down System design, Clearwater could meet the client’s requirements and deliver on schedule. The turnkey and modular design allowed the client to easily swap out their old system and install the new dry polymer system.

Contact Clearwater Industries today at (414) 365-1200 or through our contact form to learn how we can help reduce your polymer consumption and ensure long-lasting, reliable polymer preparation for your facility.