Clearwater manufactures additional equipment and establishes partnerships to provide complete solutions for specific applications. These systems are typically custom-designed to the specifications required by the application.

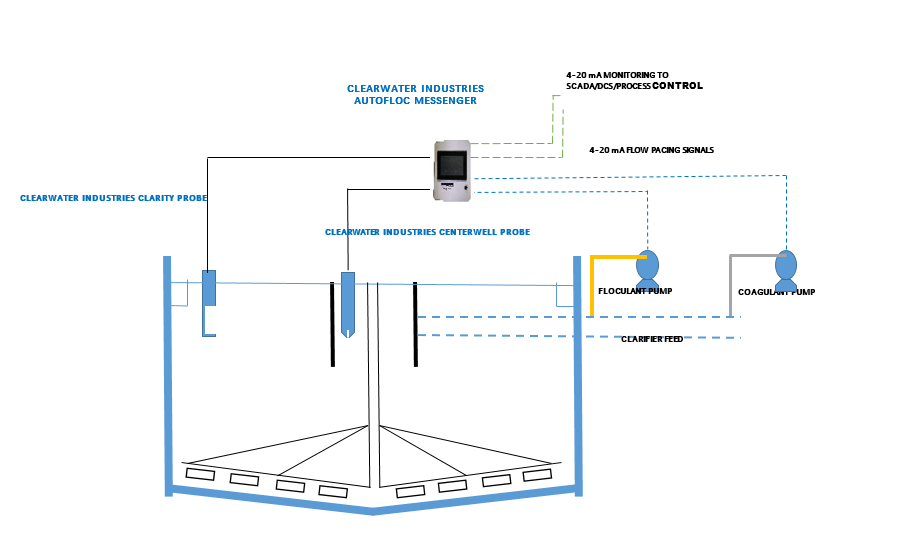

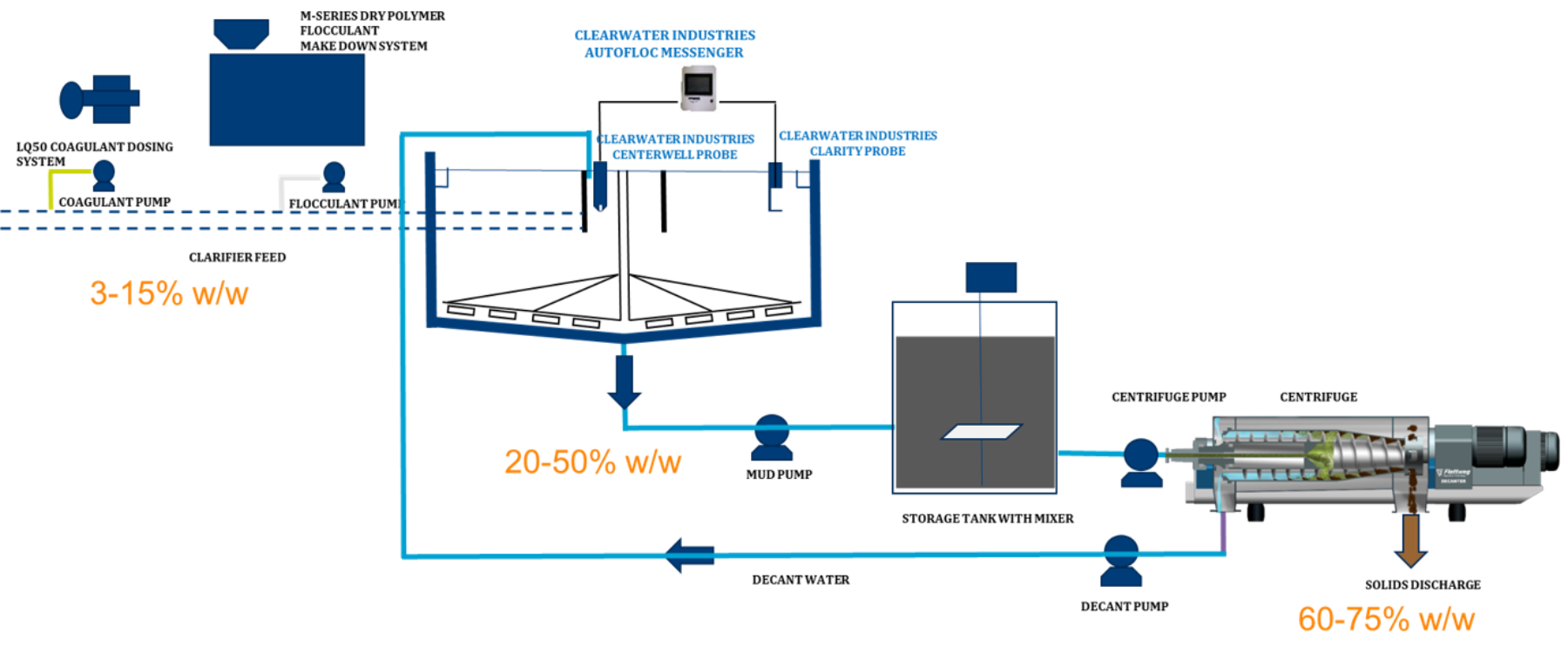

Clearwater Industries’ AutoFloc Polymer Flocculant Dosing System automates polymer dosing to ensure optimal water clarifier performance. Our AutoFloc acts as an around-the-clock operator by monitoring the water’s clarity in the center well and adjusting polymer dosing accordingly. This automation ensures polymer efficiency and minimizes consumption.

Automation of Coagulant and Polymer Flocculant Dosing

You can reduce consumption rates and improve process reliability with real-time flocculant and coagulant control.

Typical Process:

Many industries use clarifiers or thickeners to remove suspended solids from wastewater flow streams. Usually, producers add coagulants and flocculants to aid in the removal of suspended solids. These additives are mixed with the wastewater stream and directed to the center well of a clarifier or thickener.

When unadjusted for differences in suspended solids, flow rate, or reaction efficiencies, the plant may underdose, resulting in poor water quality or overdose contribution to excessive use. In extreme cases, overdosing can result in the mechanical failure of clarifier components.

Clearwater Industries Advantage:

A Clearwater Industries AutoFloc System will automate the coagulant and flocculant dosing to optimize clarifier performance.

To do this, we install our stainless steel Clearwater Industries AutoFloc Centerwell Probe in the center well of the clarifier. Infrared light absorption is detected in the flocculation zone and relayed to the Clearwater Industries AutoFloc Messenger.

The messenger adjusts the associated dosing pumps via an analog 4-20 mA output signal to account for changes in light absorption seen in the center well. A touch screen interface allows users to adjust the outputs sensitivity, air-sparging cleaning events, set alarm relays, monitor real-time readings, and review historical data. The Autofloc Messenger can output (4) analog outputs and accept (4) probe inputs.

Operators can further automate the process with Clearwater Industries AutoFloc Clarity Probe. Like the Centerwell Probe, the clarity probe uses a larger gap to detect the lower level of solids expected at the clean water overflow. This probe will provide coagulant dosing automation and clean water overflow alarms.

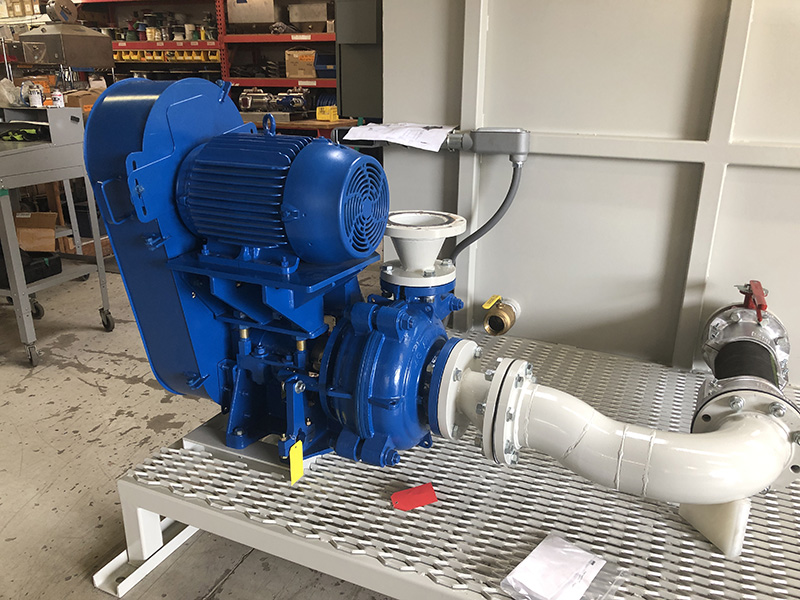

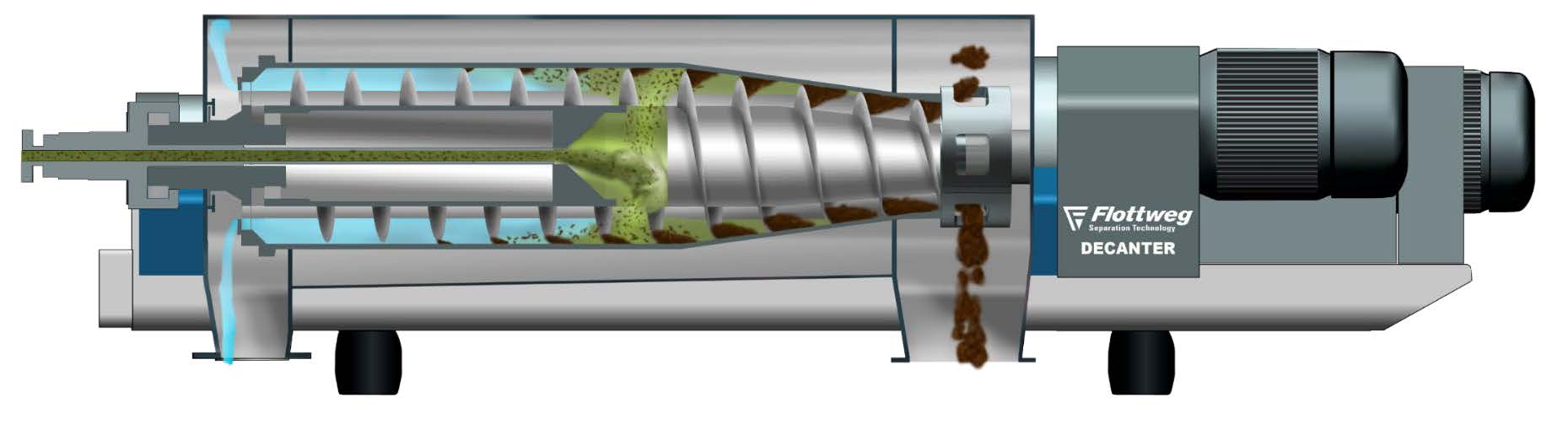

Centrifugal Slurry and Sludge Dewatering

Clearwater Industries, Inc. partners with Flottweg to provide proven centrifugal separation technology for wastewater applications. Flottwegg’s centrifuges use centrifugal force to separate liquid from solids, creating clarified water for reuse and conveyable solid matter.

Paired with Clearwater’s polymer systems and clarifiers, Flottweg centrifuges continuously dewater clarifier sludge. By combining these systems, we offer our clients a complete package for chemical conditioning, clarification, and dewatering.

With a global presence, Flottweg centrifuges provide efficient centrifugal separation for various applications and industries. Through decades of experience and innovations, the company offers a line of centrifugal separation technologies designed to meet the demands of a given application. For instance, centrifuges used in aggregate production are fabricated with high-grade stainless steel, then armor-protected with tungsten carbide and industrial-grade ceramics to protect critical wear points for years of trouble-free service.

Flottweg centrifuges provide efficient centrifugal separation for various applications and industries. Through decades of experience and innovations, the company offers a line of centrifugal separation technologies designed to meet the demands of a given application. For instance, centrifuges used in aggregate production are fabricated with high-grade stainless steel, then armor-protected with tungsten carbide and industrial-grade ceramics to protect critical wear points for years of trouble-free service.

Benefits

- Automation/Minimal Operator Attention

- Portability

- Small footprint/Infrastructure required

- No consumable filter media

- Continuous operation

- Dewater material up to 80% dry matter

- Reuse clarified water

Creating conveyable solids has made this package an absolute game-changer in the aggregate and mining industries. This allows operators to optimize their site and reduce costs by eliminating the need for multiple handling and hauling stages.