Industrial Wastewater Treatment

Clearwater Industries, Inc. is an industrial wastewater treatment equipment manufacturer and solutions provider.

Clearwater Industries, Inc. manufactures wastewater treatment equipment for industrial wastewater applications.

We provide innovative solutions for wastewater, wastewater reclamation, and water treatment in various industries. Learn how our industrial wastewater treatment products can improve your business.

- Remove solids from wastewater

- Meet discharge regulations

- Cut operating costs

- Reclaim water

Industrial wastewater is a moving target; no two applications are the same. Clearwater Industries uses its chemical, engineering, and technical experience to custom-design solutions and select stock equipment that fits your needs.

We are a single-point solution provider, from jar testing and chemical selection to commissioning and after-sale service. Our laboratory houses hundreds of wastewater treatment chemicals to find the best physical-chemical treatment solution.

Our equipment includes Chemical Preparation & Feed Systems; Stationary & Portable Clarifiers: Sedimentation, Ballasted Flocculation, Dissolved Air Flotation (DAF); Stationary & Portable Fines Recovery Systems; Process Automation Systems. Clearwater’s chemical systems provide solutions for every stage of the industrial water treatment process. Our clarifiers offer primary and secondary treatment for further wastewater purification.

Contact us and our team will work with you to find the right solution for your wastewater application.

CHEMICAL SYSTEMS

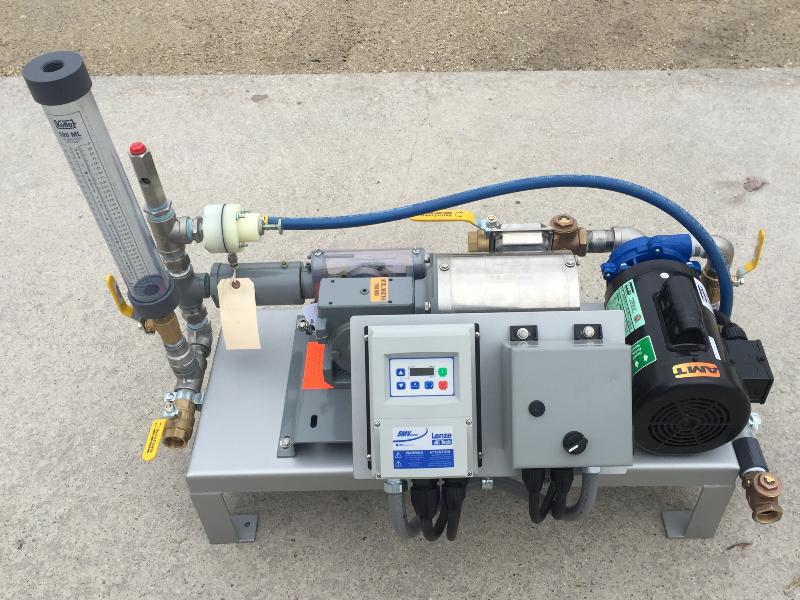

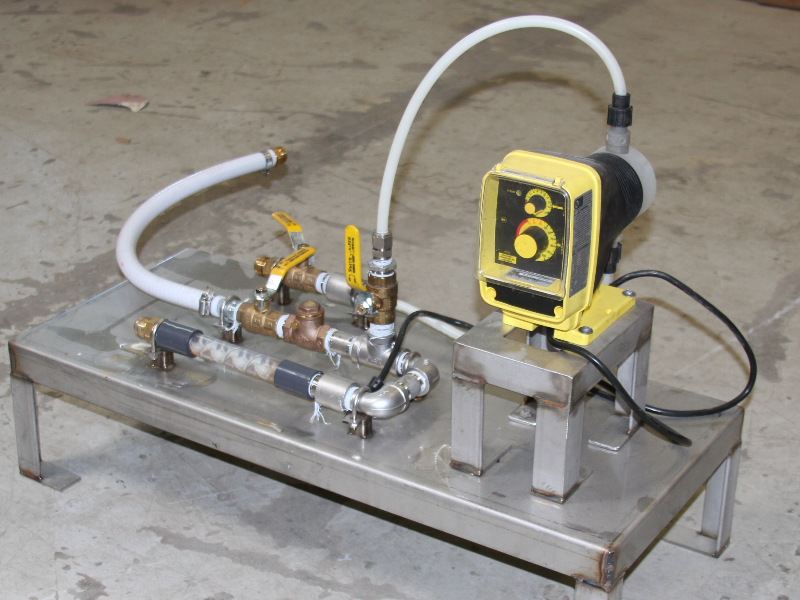

LIQUID CHEMICAL FEED SYSTEMS: LQ-SERIES

- Polymers

- Flocculants

- Coagulants

- Acids

- Bases

Clearwater’s stock and custom chemical preparation systems accurately mix and dose and uniform solution. An inline static mixer ensures a consistent chemical solution and durable designs withstand years of harsh working environments.

DRY CHEMICAL SYSTEMS: M-SERIES

- Polymer Flocculants

- Aluminum Sulfate

- Bentonite Clay

- Citric Acid

- More

All M-Series Dry Chemical Feed Systems include a lifetime warranty with the exclusive use of Clearwater’s chemical.

| Model | Solution Flowrate GPM (60 Min. HRT) | Solution Flowrate GPM (90 Min. HRT) |

|---|---|---|

| M100SS | 0-7 | 0-4.6 |

| M300SS | 0-8 | 0-5.5 |

| M500SS | 0-12 | 0-8 |

| M800SS | 0-20 | 0-12.6 |

| M3000SS | 0-38 | 0-25.3 |

| Custom | Any | Any |

Clearwater’s dry chemical systems provide accurate preparation and dosing with automated features for minimal operator attention.

- Conical Wetting Bowl

- Vogel Flow Wet Activation Venturi

- 304SS Single-Tank Three-Chamber Design

- Hydraulic and Mechanical Mixing Energies

- Automated Batching

- Flowmeter & Powder Screw Feeder FlowPacing for Consistent Solution Strength

- Removable Polypropylene Covers

- Hand/Off/Auto Controls

CONTAINERIZED CHEMICAL SYSTEMS

- Liquid Chemical LQ-Series

- Dry Chemical M-Series

Containerized Systems protect chemicals and instruments from harsh weather environments. Keep your operation running in freezing temperatures and extreme heat.

Our standard designs include fire retardant spray foam insulation, HVAC systems, single-point electrical hookup, plumbing, and LED lighting.

CLARIFIERS

STATIONARY CLARIFIERS

- High Compaction Clarifying Thickeners

- Horizontal Clarifiers

- Traditional Sedimentation

- Ballasted Flocculation

- Dissolved Air Flotation (DAF) Clarifiers

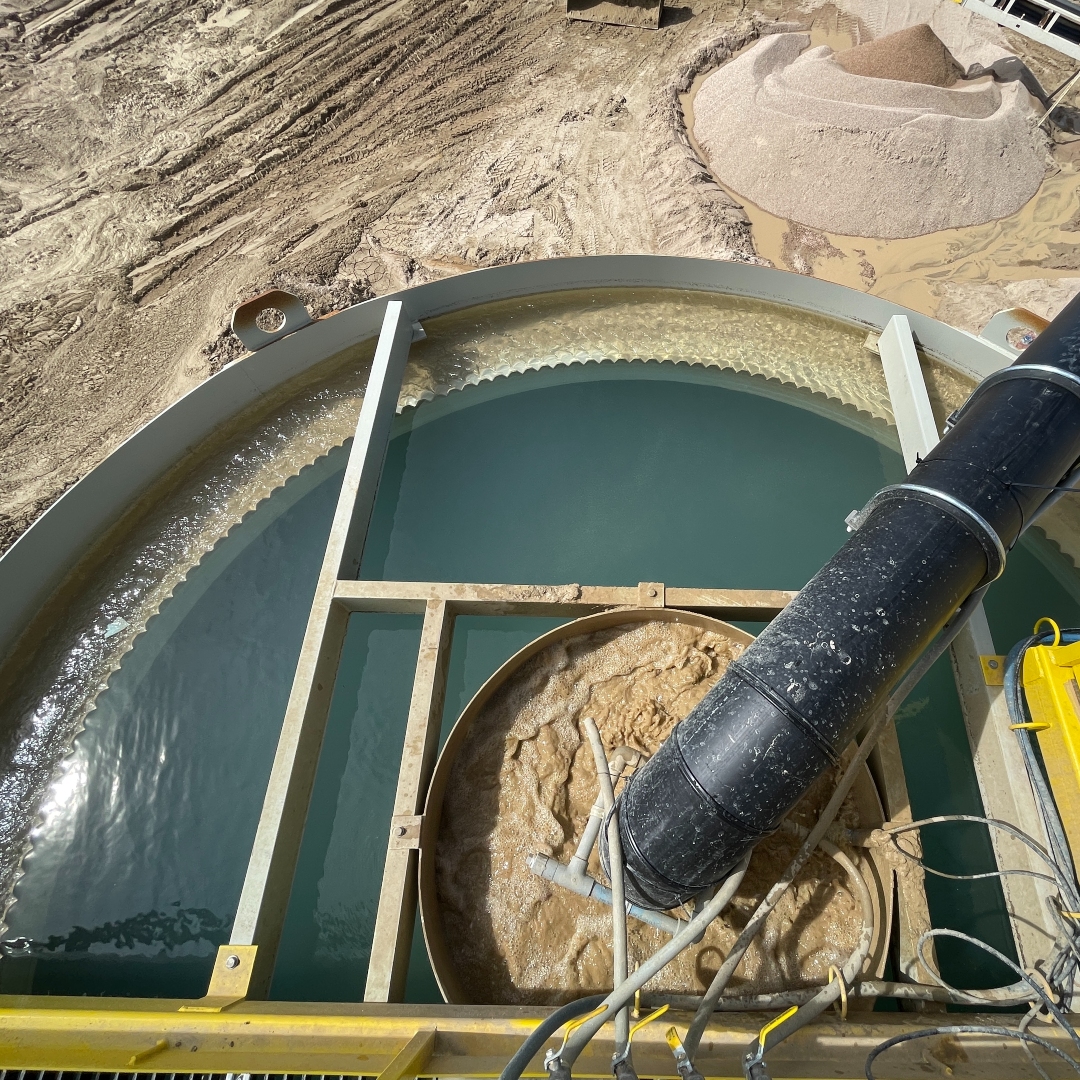

Wastewater clarification is a mainstay process for solid-liquid separation in the industry. Clearwater’s experience in industrial wastewater processing has allowed us to develop a range of clarifiers for different applications. Our stationary clarifiers are renowned for their efficiency, reliability, and innovation. Our High Compaction Clarifying Thickener achieves 50-70% solids by weight.

PORTABLE CLARIFIERS

- Traditional Sedimentation

- Ballasted Flocculation

Clearwater Industries is a pioneer in portable clarification. Our turnkey designs treat 300-2,000 GPM flowrates with 90% water recovery and 30-50% solids by weight sludge discharge. Each unit includes a climate-controlled operator room and integrated chemical feed systems.

FINES RECOVERY SYSTEMS

- Stationary

- Portable

Clearwater’s Fines Recovery Systems separates particles based on size and dewaters material to a stackable state. All systems are automatic with manual override and integrate with our clarifiers and chemical feed systems.

AUTOFLOC DOSING SYSTEM

The AutoFloc Dosing System uses infrared light absorption to automate coagulant and flocculant dosing. Automated dosing reduces chemical consumption rates and improves process reliability. Unlike other systems that have to pull and analyze samples, the AutoFloc accounts for flocculation changes in real-time.

An infrared light absorption Centerwell Probe relays data to a touchscreen AutoFloc Messenger that uses 4-20 mA output signals to adjust dosing pumps.

The AutoFloc messenger features a touch screen interface for users to adjust the outputs sensitivity, probe air-sparging cleaning events, set alarm relays, and monitor real-time or historical data.

INDUSTRIES & APPLICATIONS

CASE STUDIES

CONTACT US

Tell us about your challenges. Our team will contact you to discuss a tailored solution based on our experience.